Wedoany.com Report-Nov. 12, Fluor Corporation, based in Irving, Texas, announced that it has received a contract from LanzaJet for the front-end engineering and design (FEED) of a new sustainable aviation fuel (SAF) production hub in North Yorkshire, England. The project, named Project Speedbird, is a joint development between LanzaJet and British Airways. Fluor stated that the value of the contract, which remains undisclosed, will be recognized in the third quarter of this year.

Mike Alexander, Group President of Project Execution at Fluor Corporation, said: “Project Speedbird marks a pivotal advancement in the global effort to decarbonize aviation. By accelerating the adoption of sustainable fuel technologies, this project will help redefine the future of flight. Fluor is proud to bring our engineering and design expertise to this visionary initiative.”

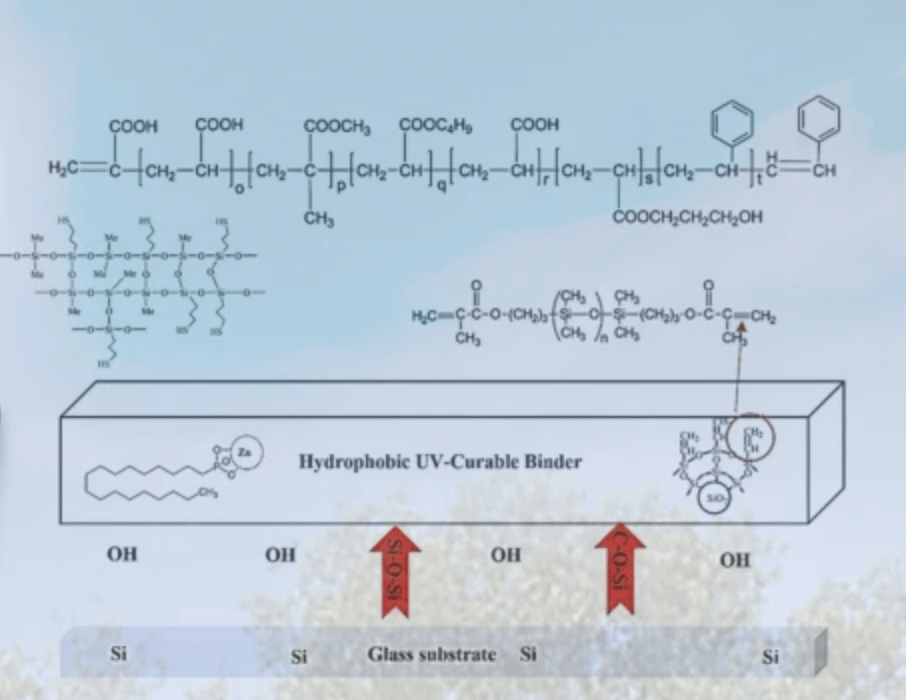

The North Yorkshire facility will apply LanzaJet’s Alcohol-to-Jet (ATJ) technology, which converts second-generation ethanol—produced from agricultural residues and woody biomass—into sustainable aviation fuel. This process aims to create a lower-carbon alternative to conventional jet fuel, contributing to the aviation industry’s decarbonization goals.

British Airways plans to use the SAF produced at Project Speedbird to significantly reduce its carbon footprint. The airline expects to cut around 230,000 tonnes of carbon emissions annually, which is equivalent to the emissions generated by approximately 26,000 domestic flights.

Jimmy Samartzis, Chief Executive Officer of LanzaJet, emphasized the project’s strategic importance: “Project Speedbird is the next commercial-scale facility in our portfolio that LanzaJet is developing, working closely with British Airways. It is an important step in the continued scale-up of our leading sustainable fuels technology. Partnering with the globally recognized engineering, procurement, and construction company Fluor Corporation shows our commitment to the highest standards in project execution.”

The new facility will be located in Teesside, United Kingdom, and is designed to produce more than 90,000 tonnes (30 million gallons) of SAF and renewable diesel per year. The location was chosen for its strategic advantages, including access to existing energy infrastructure, a supportive industrial network, and a highly skilled local workforce.

Project Speedbird represents a major milestone for the UK’s efforts to expand domestic SAF production capacity and support the transition toward cleaner aviation fuels. Once completed, the facility will contribute to advancing the country’s sustainability objectives while supporting economic development in the Teesside region.

Through this collaboration, Fluor, LanzaJet, and British Airways aim to combine engineering expertise, innovative fuel technology, and operational experience to deliver a model for large-scale SAF production. The initiative underscores the aviation industry’s increasing focus on sustainable fuel solutions and its commitment to reducing lifecycle emissions in air transport.