Wedoany.com Report-Dec.1, On November 28, 2025, the Association for the Decarbonization of Industry (VZDI) and its partners officially opened a pioneering methane pyrolysis pilot plant at the V-ZUG production site in Zug, Switzerland. The facility, developed through collaboration between 16 companies, the research institute Empa, and supported by the canton of Zug, represents an investment exceeding CHF 8 million and supports Switzerland’s goal of reaching net-zero emissions by 2050.

The new methane pyrolysis plant on the V-ZUG production site.

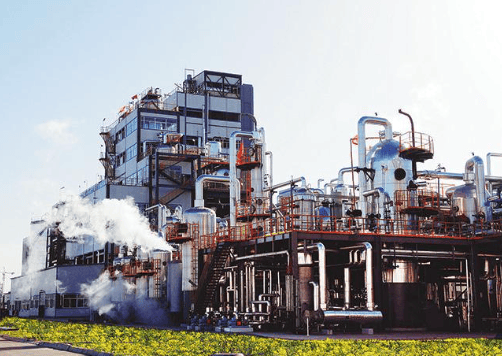

The innovative technology uses microwave-generated plasma to split methane – the primary component of natural gas and biogas – into hydrogen gas and solid carbon. Unlike conventional methods, this process prevents the release of carbon dioxide into the atmosphere. The solid carbon produced can be utilized as a valuable raw material, for example as carbon black in tires, batteries, adhesives, or sealants, or incorporated into concrete and asphalt as a permanent carbon store.

The newly inaugurated plant will produce approximately 22 tons of hydrogen per year while avoiding around 240 tons of CO₂ emissions annually. The hydrogen will directly replace fossil natural gas in V-ZUG’s enameling furnace, enabling the company to eliminate the last remaining source of process-related CO₂ emissions at the site and advance the decarbonization of its manufacturing operations.

The project was coordinated by VZDI with Empa serving as the main research partner. Participating companies include Accelleron, AVAG, AMAG, Holcim, Metall Zug, Partners Group, Sakowin, SHL Medical, Siemens, Sika, Sulzer, Swiss Safety Center, Tech Cluster Zug, V-ZUG, VZ Depotbank, and WWZ. The canton of Zug provided additional backing. Each partner contributed technical knowledge and funding to accelerate practical solutions for industrial sustainability.

Christian Bach from Empa, co-initiator and technical project manager, emphasized the practical benefits of the technology: “The advantage of this approach is that it does not require any new infrastructure and can be implemented quickly worldwide.”

Looking ahead, the initiative forms part of a broader vision. Researchers at Empa, under Bach’s leadership, have also developed a flexible methanation system already operating in a separate pilot facility. When combined with large-scale solar-powered methanation in suitable regions, existing gas networks for transport, and local pyrolysis at the point of use, the overall process can achieve negative CO₂ emissions without requiring new pipelines or transport systems.

The Zug plant serves as a central element in VZDI’s strategy to establish a circular, emission-free methane economy. It enables the use of renewable methane sources, produces clean hydrogen for industry, and creates pathways for active carbon removal. Ongoing cooperation between research institutions, industrial companies, and public authorities continues to explore scalable models that can operate economically while contributing to global atmospheric decarbonization efforts.