Wedoany.com Report-Dec.11, Construction of the 2.7km cut-and-cover green tunnel near Greatworth in West Northamptonshire is progressing steadily as part of the HS2 high-speed rail project. This structure, one of five green tunnels on the route, is being built within a shallow cutting and features separate northbound and southbound sections formed in an 'M' shape using precast concrete segments. The design draws from established methods used on high-speed lines in France, facilitating rapid offsite fabrication and efficient on-site assembly.

Greatworth is HS2's longest cut-and-cover tunnel

The first kilometre of the Greatworth tunnel has now been completed, enabling the temporary realignment of the B4525 road. This adjustment clears the way for excavation and assembly of the subsequent section, allowing work to continue through the winter period without interruption.

A parallel green tunnel at Chipping Warden, employing a comparable precast approach, has informed ongoing refinements at Greatworth. Construction at Chipping Warden commenced earlier and highlighted initial challenges with productivity, as the original timeline proved ambitious during the 2022/23 period. In response, HS2 Ltd collaborated closely with its primary contractor, EKFB—a joint venture of Eiffage, Kier, Ferrovial Construction, and Bam Nuttall—to introduce targeted enhancements to workflows and logistics.

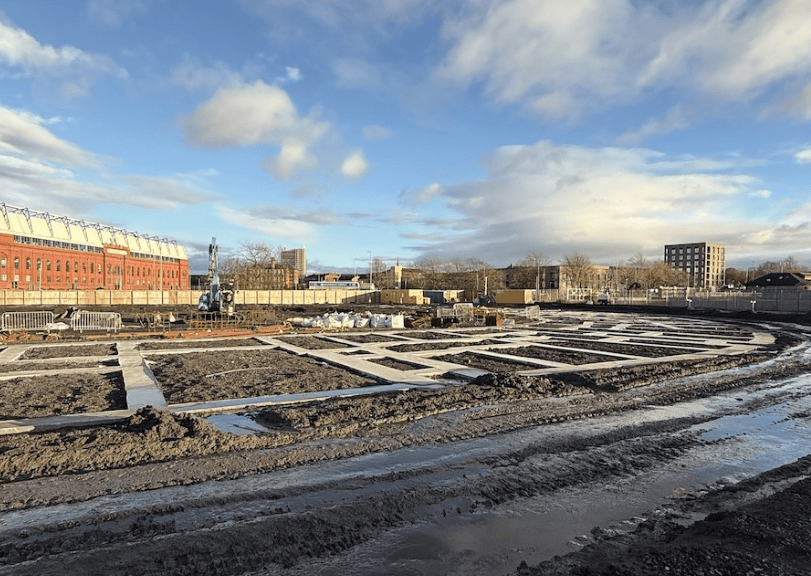

These measures have substantially increased efficiency, with segment installation rates rising from approximately two per day at Chipping Warden's outset to five or six per day at both sites in 2025. The process unfolds in defined phases: first, the cutting is excavated, followed by placement of a blinding layer to create a stable concrete foundation. To accelerate this step, steel reinforcement bars are now supplied as pre-connected roll mats, taped together with mild steel for swift deployment before the concrete pour.

Subsequently, five precast segments are positioned to form each 'M'-shaped unit, with optimised delivery sequences and installation techniques minimising delays and ensuring precise alignment. Once assembled, a concrete invert slab is cast to support the future track bed; this phase has been expedited by redirecting concrete supply routes and incorporating prefabricated reinforcement cages, effectively doubling the pouring speed.

The upper valley of the 'M' structure is then infilled with an aerated concrete mixture, which installs more consistently and rapidly than traditional aggregate fills. All modifications were validated beforehand on a dedicated test section at Chipping Warden, confirming their reliability under site conditions.

Direct management of logistics by EKFB has streamlined operations, reducing coordination between specialised teams in the confined tunnel face area and incorporating buffers to accommodate unforeseen setbacks. These adaptations collectively enhance schedule resilience while maintaining safety and quality standards.

EKFB senior engineer Chris Barrett noted: "Implementing the construction improvements and learnings from the Chipping Warden tunnel has allowed us to accelerate the unit installation of the Greatworth tunnel. This means that we can reopen roads and further connect our communities. Opening these roads unlocks the next phase of excavation work on the tunnel which will allow us to progress with construction through the winter months."

Insights from these sites are being integrated into the similar precast green tunnel at Wendover in Buckinghamshire. The remaining two green tunnels—Copthall near London and Burton Green in Warwickshire—are shorter and utilise a cast-in-situ method rather than precast segments.

Amid broader project advancements, HS2 chief executive Mark Wild is overseeing a comprehensive review to optimise delivery timelines and costs across civil engineering works. This focus on continuous improvement underscores the commitment to efficient infrastructure development that supports regional connectivity and economic growth.