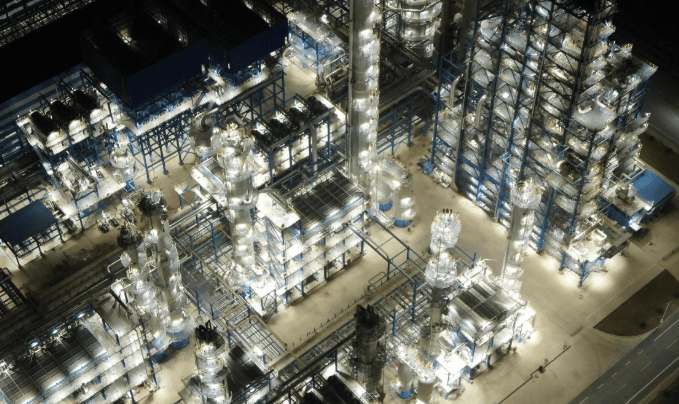

Wedoany.com Report-Dec.22, MAIRE Group announced that its nitrogen technology licensing company, Stamicarbon, has secured a contract to provide licensing, a Process Design Package (PDP), and core equipment featuring its NX STAMI Urea™ technology for a new urea plant to be built by a fertilizer producer in Eastern China. The urea plant is designed with a daily production capacity of 2,700 tons.

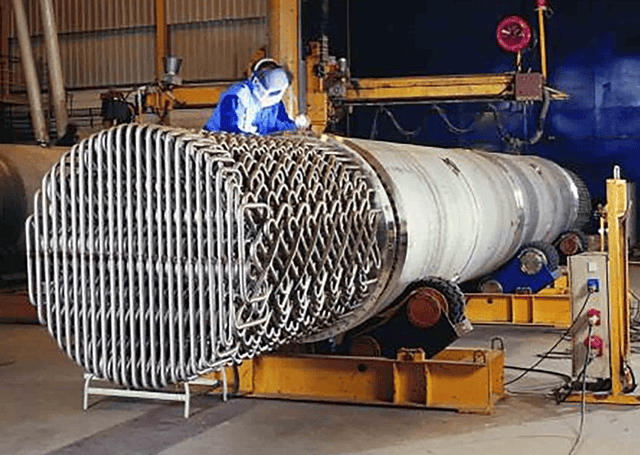

The plant will utilize Stamicarbon's ultra-low energy consumption solution, which is part of its proprietary NX STAMI Urea™ technology portfolio. This technology, through innovative high-pressure steam utilization and an efficient pool reactor design, is expected to reduce steam consumption by approximately 35% and cooling water usage by about 16% compared to conventional processes. Key equipment, such as the pool reactor and stripper, will be constructed using E-type super duplex stainless steel, applying Stamicarbon's expertise in materials science. Furthermore, the company's granulation tower design aims to ensure product granule quality and maintain biuret content at a low level.

Commenting on the project, Fabio Fritelli, Managing Director of NEXTCHEM, stated: "This project marks the tenth global application of the ultra-low energy consumption technology and the eighth in China. With seven plants already in operation, it fully demonstrates our benchmark position in energy efficiency for urea production. This contract further solidifies NEXTCHEM's presence in the region and underscores our commitment to enhancing sustainability in the fertilizer industry through technological advancement." This ultra-low energy consumption technology solution has been adopted in multiple global projects to improve energy efficiency and reduce operating costs.

This urea project represents one of the latest application cases in China based on the NX STAMI Urea™ ultra-low energy consumption technology, aiming to support energy efficiency improvement and sustainable development in fertilizer production.