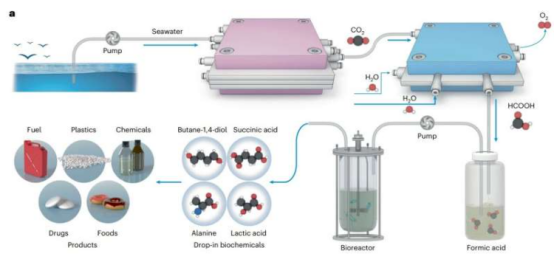

The ocean, as Earth's largest carbon sink, absorbs approximately 25% of anthropogenic CO₂ emissions, but this process leads to ocean acidification, threatening ecosystem stability. Recently, Nature · Catalysis reported an innovative study: a research team has developed a system to efficiently capture CO₂ from seawater and convert it into a biodegradable plastic precursor, offering a sustainable solution for industrial chemical production.

The system, designed by lead researcher Natsukawa and colleagues, consists of two parts: first, an electrocatalyst converts CO₂ in seawater into pure formic acid; then, a genetically engineered Halomonas bacterium further transforms it into succinic acid—a key raw material for producing biodegradable polybutylene succinate. The system achieves a carbon capture efficiency exceeding 70%, with low energy consumption of 3kWh per kilogram of CO₂, continuous operation for 536 hours, and competitive costs of $229.9 per ton of CO₂ processed. In scale-up experiments, the fermenter achieved a yield of 1.37g per liter, validating the system's scalability.

The research team noted that by optimizing electrodes and microbial catalysts, the system could also produce fuels, pharmaceuticals, food additives, and other chemicals. Although current yields and integration levels require further improvement to meet industrial demands, this breakthrough opens new pathways for CO₂ valorization and is expected to drive the chemical industry toward low-carbon transformation. Natsukawa stated: "Our goal is to transform CO₂ from an environmental burden into a valuable resource."