As global industries transition toward intelligent and sustainable production methods, Missouri University of Science and Technology doctoral graduate Joshua Adu Afari has developed a new model to help manufacturers reduce costs and carbon emissions without requiring additional resources. The research was published in the International Journal of Interactive Design and Manufacturing, co-authored by Dr. Afari, engineering management professor Dr. Abhijit Gosavi, and emeritus professor Dr. Robert Marley.

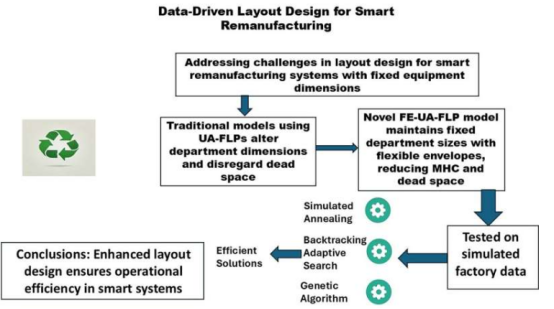

Afari's research focuses on "remanufacturing," which involves repairing old products to make them reusable. He improved previous models while keeping dimensions unchanged, thereby reducing material handling costs. "Reducing material handling costs will automatically lower the total production cost of the product, which benefits consumers as well," Afari said. Professor Marley noted that this research highlights the importance of advanced manufacturing and helps enhance economic viability in places across Missouri and the United States where manufacturing was previously difficult to conduct. "Using existing facilities to reduce costs helps keep businesses local," Marley said.

Professor Gosavi stated that the modeling approach in this project provides researchers and manufacturers with a way to test new ideas in a real-world environment. "The model is abstract, and the system is a real-world version. You can adjust, modify, and experiment with the model without interrupting the actual production process," Gosavi said. This remanufacturing research was funded by the U.S. National Science Foundation and published by Springer Nature. Afari's primary goal is to make manufacturing smarter, more efficient, and responsible for future generations. "This is about saving time, reducing waste, producing what is needed, while protecting the environment and keeping manufacturing strong," Afari said.