Recently, as easily extractable oil resources in Russia are diminishing, developing hard-to-reach minerals and expanding extraction methods has become an inevitable trend. New technologies make it possible to access the country's extra-reserve stocks, which were previously uneconomical. In this context, scientists at Perm State Technical University have developed a novel cable rod design that promises positive changes for oil extraction.

Currently, Russia's oil and gas production industry is focused on expanding balanced oil reserves. Developing extra-reserves (primarily hard-to-extract oil) is costly and requires new technologies but holds significant strategic importance. Directional drilling and sidetracking are one of the most promising methods, where cable rods enable efficient operation of oil extraction equipment.

Traditional cable rods are made of closed steel wire ropes twisted together, secured to the device with special fasteners, with the bottom connected to the pump plunger and the top to the pumping unit at the well surface. During pumping, the oil rods reciprocate and move up and down, causing extension or even contraction. However, traditional rod designs cannot withstand such loads, leading to repeated bending of the rope, defects (such as gaps between wires or structural integrity damage near the seal), and quick failures. This necessitates pump shutdowns for replacement and incurs associated costs.

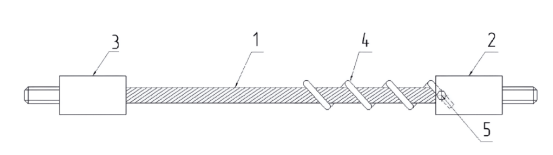

To address this issue, previous solutions involved applying a protective polymer coating to the rod's outer surface. However, the coating wears due to friction, contaminates the oil, and increases production costs. Scientists at Perm State Technical University have improved the design by adding a metal spiral retainer to the lower seal. This retainer, made of corrosion-resistant steel (such as grade 20X13), increases the stiffness of components near the lower seal, preventing failure. Compared to the rope, the retainer's twist direction is opposite, allowing for even load distribution.

Technical staff at the institute explained that the spiral can be secured via interference fit, screws, or welding, making installation simple without additional equipment—it can even be installed on ready-to-use rods. The twist diameter and pitch of the retainer are determined by the rope diameter and can be applied partially while twisting along the cable. This device enhances the stiffness of existing manufactured and used cable rods.

The simple and effective solution proposed by Perm State Technical University scientists can extend the service life of cable pump rods in directional wells, reduce maintenance costs, improve production profitability, and provide strong support for the development of Russia's oil extraction industry.