Solid-state battery developer QuantumScape recently announced the integration of its brand-new manufacturing process, "Cobra," into its production line. This process increases the speed of key heat treatment steps by approximately 25 times, significantly optimizing the scalable production workflow for solid-state lithium-metal batteries.

QuantumScape noted in a press release that compared to the previous-generation "Raptor" process, Cobra offers a ~25x improvement in heat treatment speed and occupies a fraction of the physical space per film start—key advantages in designing a scalable gigafactory production line. Cobra has now become the baseline standard for separator production on the company's QS-0 assembly line.

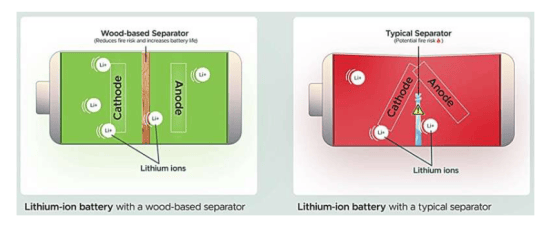

The core component of QuantumScape's solid-state battery is its proprietary ceramic separator material, which requires high-temperature heat treatment (sintering) to form a dense, uniform layer. However, conventional heat treatment is time-consuming and energy-intensive, long constraining the large-scale production efficiency of ceramic-based solid-state batteries and increasing manufacturing costs.

As an upgrade to the "Raptor" system, the Cobra process directly addresses this bottleneck. It not only drastically shortens the heating phase duration but also significantly reduces the equipment footprint per unit output. QuantumScape stated that faster production speeds and smaller space requirements are core elements of economic modeling and capacity planning for large battery factories.

Dr. Siva Sivaram, QuantumScape's CEO, commented: "The team's breakthrough in Cobra technology exemplifies our progress in scaling solid-state battery production. This process will accelerate the commercialization timeline for next-generation batteries."

With the new process now operational, QuantumScape will continue advancing production of its next-generation battery (B-sample). In the automotive industry, the transition from A-sample to B-sample is a key phase in the product validation cycle: A-samples are early prototypes for initial performance assessment, while B-samples use mass-production tools and processes, representing a more mature design. Automotive partners will conduct comprehensive testing and validation based on B-sample batteries to lay the foundation for final mass production.

QuantumScape did not disclose specific quantitative targets for capacity improvement from the new process but emphasized that the technological breakthrough will further solidify its competitive edge in solid-state batteries. The company is currently collaborating with multiple automakers to advance battery commercialization.