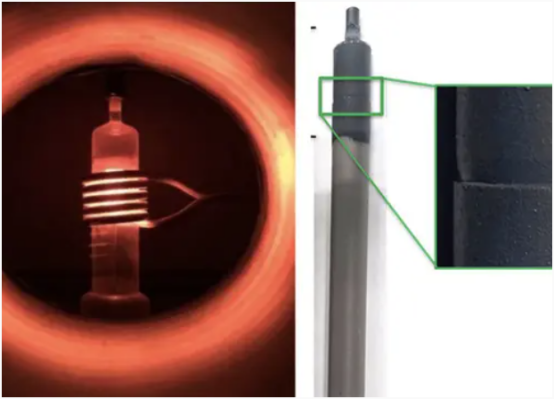

San Diego-based General Atomics Electromagnetic Systems (GA-EMS) has announced a major milestone for its silicon carbide (SiC) nuclear fuel cladding technology: its proprietary localized SiC joining process has successfully passed performance testing in a simulated pressurized water reactor (PWR) corrosive water environment, clearing the path for in-reactor demonstration of the SiGA® cladding.

GA-EMS reports that the patented localized SiC joining method recently demonstrated excellent performance under simulated PWR coolant conditions. The technique hermetically seals fuel rods to prevent exposure of nuclear fuel pellets to high-temperature water, creating a complete safety solution. The SiGA cladding, made of multilayer silicon carbide composite, can withstand temperatures six times higher than cladding in existing light-water reactors, dramatically improving high-temperature tolerance and irradiation resistance.

"The localized joining process not only shortens processing time but also enables scalable, high-efficiency domestic manufacturing, delivering safer accident-tolerant fuel cladding to nuclear power plants," said Scott Forney, President of GA-EMS. He emphasized that the combination of SiGA cladding and the joining process fully and safely contains solid fuel, meeting the design requirements of both current and future reactors.

Nuclear fuel cladding serves as the critical barrier between reactor coolant and fuel pellets; its hermetic integrity is essential for plant safety. GA-EMS's SiGA cladding is assembled by stacking fuel inside cladding tubes and sealing both ends to form a gas-tight structure. According to the company's press release, the technology has already validated the irradiation resistance of ceramic joints in Oak Ridge National Laboratory's High Flux Isotope Reactor and is now evaluating long-term stability under PWR high-temperature, high-pressure, and corrosive coolant conditions.

"Joints manufactured using the localized silicon carbide joining process maintained hermeticity after 180 days of exposure in Westinghouse's reactor coolant test facility, providing critical data for final validation," noted Dr. Christina Back, Vice President of Nuclear Technologies and Materials at GA-EMS. She revealed that the company plans concurrent testing of joint performance under both corrosive coolant and neutron irradiation environments at Idaho National Laboratory's Advanced Test Reactor.

The SiGA cladding material retains structural stability at temperatures up to 1900°C, far exceeding the limits of conventional metal cladding. The technology enables higher reactor power density, longer fuel life, and lower operating costs. GA-EMS has already signed contracts with the U.S. Department of Energy (DOE) under the Accident Tolerant Fuel Program to advance commercialization of silicon carbide cladding in U.S. nuclear reactors.