Rice University, in collaboration with multiple institutions, has developed a transparent glass coating based on boron nitride that effectively reduces energy loss through windows. Fabricated by embedding carbon atoms into the boron nitride lattice, the coating combines high transparency, scratch resistance, and environmental durability, making it ideal for buildings in cold climates.

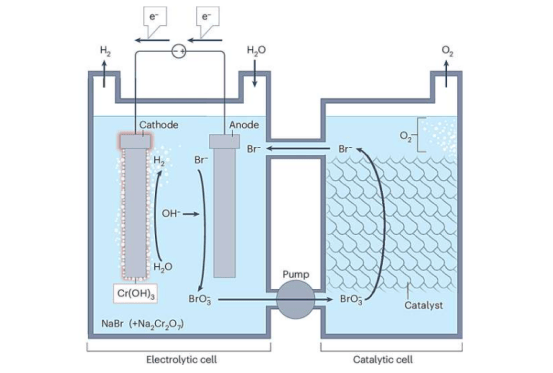

Published in Advanced Materials, the team's results show the boron nitride coating achieves 2.9% energy savings compared to conventional materials in simulations for cities like New York and Beijing. With approximately 3.8 billion square meters of new window area added annually in the U.S., this technology has significant potential to cut heating energy use. Unlike traditional low-emissivity (low-E) coatings that are moisture-sensitive and must be placed on the interior side of windows, the boron nitride coating can be applied on the exterior thanks to its superior durability.

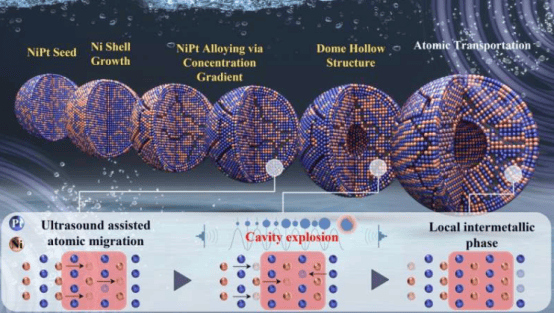

Professor Pulickel Ajayan of Rice University stated: "Carbon doping dramatically lowers the emissivity of boron nitride—this changes the game." The team used pulsed laser deposition to deposit boron nitride vapor onto glass at room temperature, eliminating the need for high-temperature processing. Lead author Abhijit Biswas noted that this synthesis approach enables scalable production of boron nitride coatings.

While raw material costs for the boron nitride coating are lower than silver or indium tin oxide used in commercial low-E glass, researchers emphasize that overall cost must account for durability and process maturity. Professor Yi Long from the Chinese University of Hong Kong said: "Its outdoor weather resistance makes it the first low-E solution designed for exterior windows, with significant potential in densely built areas."

Beyond energy savings, the boron nitride coating can be extended to substrates such as polymers and textiles. The research team includes members from Arizona State University, Cornell University, and others who jointly validated the coating's light transmittance and energy-saving performance.