Researchers at the U.S. Department of Energy's Oak Ridge National Laboratory (ORNL) have developed a lighter, more cost-effective current collector that promises to improve electric vehicle battery performance, delivering longer range and ultra-fast charging.

To strengthen the competitiveness of U.S. transportation, domestically produced EV batteries capable of fast charging and long range are essential. However, the higher energy density needed for extended range often comes at the expense of charging speed and battery lifespan.

In this breakthrough, ORNL researchers integrated a novel current collector — a critical battery component — to create a battery that combines outstanding energy density with sustained extreme-fast charging capability. The battery can recover at least 80% of its charge in 10 minutes. By significantly reducing metal usage, particularly high-demand copper, the technology also eases pressure on U.S. supply chains.

Lead researcher Georgios Polyzos said the innovation dramatically cuts near-critical materials, with substantially less copper and aluminum required, while greatly increasing the energy density achievable with a 10-minute charge.

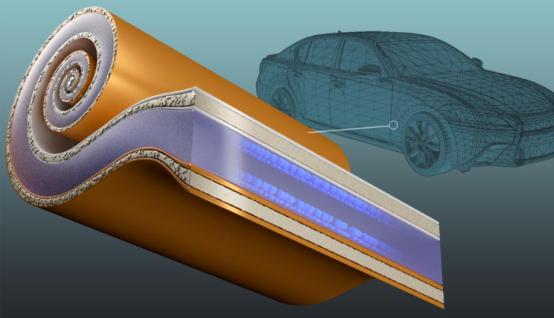

Current collectors conduct current from the battery's active material to the external circuit and are typically made of metal foil — copper for the anode and aluminum for the cathode. These metal foils add weight to both the battery and the vehicle, increasing the energy needed to drive.

The new current collector, manufactured by industry partner Soteria Battery Innovation Group, consists of a polymer sandwiched between ultra-thin layers of copper or aluminum. ORNL researchers found this design reduces current collector cost by 85%, provides 27% more energy for longer range, and retains high energy density even after 1,000 cycles. Performance matches conventional collectors, but weight is only about one-fourth, enabling EVs to travel farther on the same charge.

To ensure scalability and commercialization potential, ORNL researchers produced coin cells and pouch cells using industry-standard processes at their open-access battery manufacturing facility.

Polyzos noted that while thinner materials are prone to wrinkling, the team identified precise parameters to successfully incorporate them into roll-to-roll production. Other experimental current collectors often require expensive, complex manufacturing incompatible with standard roll-to-roll methods.

The ORNL findings, published in Energy & Environmental Materials, highlight the potential of metallized polymer current collectors to "completely transform roll-to-roll battery manufacturing and significantly enhance lithium-ion battery performance metrics for electric vehicle applications."

Brian Morin, CEO of Soteria in South Carolina, said that although the plastic film adds physical resistance, ORNL helped the company understand how to leverage the technology for fast charging. Removing 80% of the metal increases processing difficulty, yet ORNL proved fast charge/discharge remains achievable. Soteria tests also show the polymer improves battery safety: in an internal short circuit, a brief energy surge corrodes the plastic film, pulling the metal away — the current collector acts like an internal circuit breaker, eliminating ~90% of fires caused by lithium-ion battery short circuits.

The metallized polymer current collector research was funded by the U.S. Department of Energy's Advanced Materials and Manufacturing Technologies Office (AMMTO). Other ORNL researchers involved include Sergiy Kalnaus, Sabine Neumayer, Wheatley Steenman, and Jaswinder Sharma.