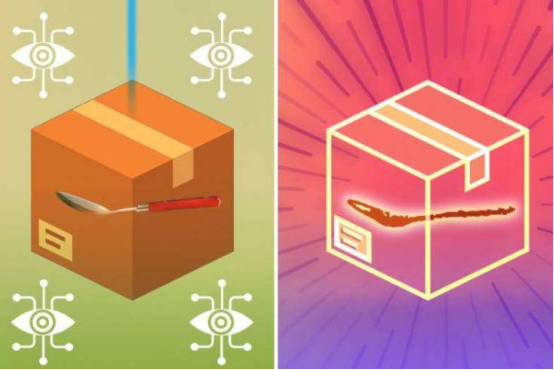

MIT researchers have successfully developed a novel imaging technology called mmNorm, which uses millimeter-wave signals to create precise 3D reconstructions of line-of-sight obstructed objects. With this technology, quality control robots in warehouses can peer through cardboard shipping boxes to detect a broken mug handle buried under packing peanuts. Millimeter waves can penetrate common obstacles like plastic containers and interior walls, reflecting off hidden objects. The mmNorm system collects these reflections and feeds them into an algorithm to estimate the object's surface shape.

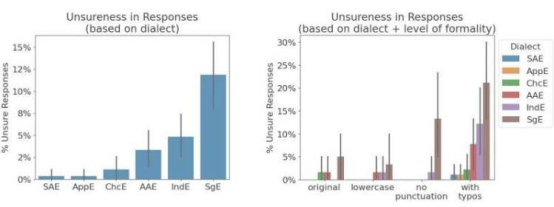

mmNorm achieves up to 96% reconstruction accuracy for everyday objects with complex curved shapes, far surpassing the 78% accuracy of the most advanced baseline methods, without requiring additional bandwidth. This efficiency makes it suitable for factories, assisted living facilities, and other scenarios. For example, in factories or homes, robots can use mmNorm to distinguish tools in drawers and identify handles, enabling more effective grasping and manipulation of objects. Fadel Adib, Associate Professor in MIT's Department of Electrical Engineering and Computer Science, stated: "We needed to find a way to use these signals very differently from how they've been used for more than half a century to unlock new types of applications."

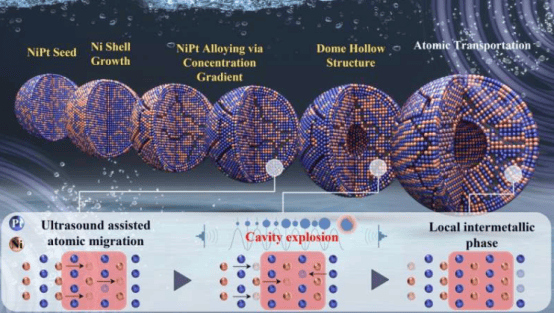

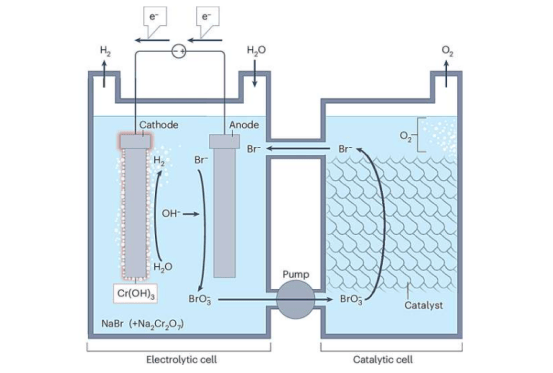

Traditional radar technologies can detect hidden objects but produce coarse image resolution for small items. MIT researchers discovered that existing back-projection techniques overlook specular reflection characteristics. mmNorm estimates surface normals—the direction of a surface at specific points in space—and combines them with mathematical formulas to reconstruct 3D objects. Researchers attached radar to a robotic arm to create an mmNorm prototype, estimating surface curvature by comparing signal strengths from different positions. The technology also distinguishes multiple objects and performs well across various materials but fails for objects behind metal or thick walls.

Tests showed mmNorm reduced reconstruction errors by about 40% for over 60 complex-shaped objects and improved position estimation accuracy. In the future, mmNorm could integrate with augmented reality headsets to help factory workers visualize realistic images of occluded objects. It could also enhance security and defense applications, improving precision in airport scanners or military reconnaissance. Researchers aim to boost resolution, enhance imaging of low-reflectivity objects, and enable penetration of thicker occlusions.