On July 31, the U.S. stellarator commercial fusion company Thea Energy published its latest research in IEEE Transactions on Applied Superconductivity. The company's developed "Canis" 3×3 high-temperature superconducting (HTS) planar coil array successfully validated the core capability of stellarator magnetic field shaping, with closed-loop control error of only 0.56%-0.60%, breaking through the complexity and cost limitations of traditional modular coil technology and opening a new path for commercial fusion devices.

Stellarators, as key devices for controlled nuclear fusion, have long been constrained by the complexity of "modular coils." These non-planar coils require strict tolerances in three-dimensional space, resulting in high manufacturing difficulty and costs. The U.S. NCSX (National Compact Stellarator Experiment) project was once forced to terminate due to coil issues.

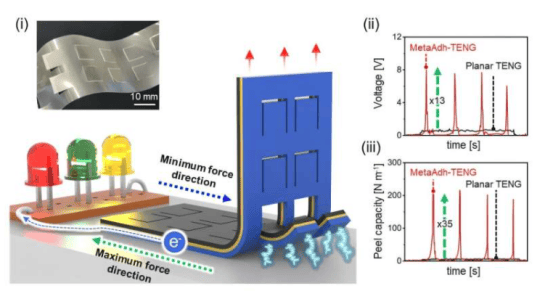

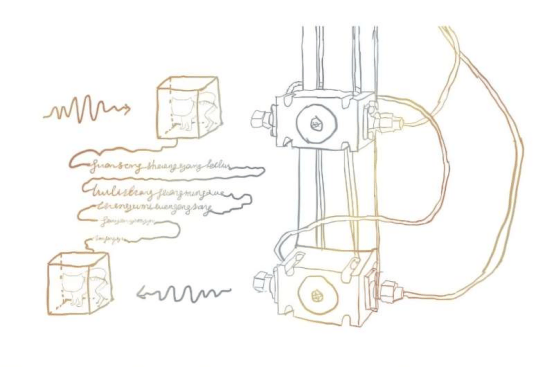

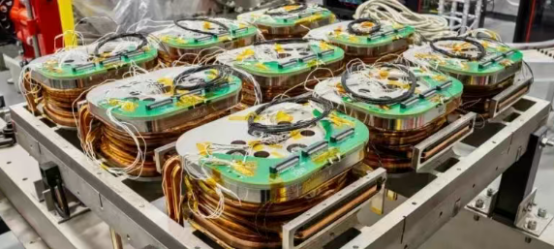

Thea Energy was founded in 2022, with its technology originating from patents at the Princeton Plasma Physics Laboratory (PPPL): using a combination of "planar toroidal coils + planar shaping coils" to generate three-dimensional magnetic fields. Among them, the shaping coils are arranged in a "tile-like" manner outside the vacuum vessel, forming detachable "field shaping units (FSUs)," reducing manufacturing complexity and simplifying maintenance. This design allows Eos (the company's first integrated fusion system) to form optimized magnetic fields without complex modular coils. In March this year, the company successfully demonstrated the world's first superconducting planar coil magnet array.

To validate technical feasibility, Thea Energy built the "Canis" 3×3 magnetic pixel array consisting of 9 HTS planar coils, with core breakthroughs in three aspects:

In terms of materials and performance, rare-earth barium copper oxide (REBCO) superconducting tape was selected. Based on engineering validation under a 20K, 14T combined magnetic field: when the conductor total field strength exceeds 14T, it still maintains a winding current density of ≥200A/mm² (design value about 30% of the material critical current). Single coil simulation shows a minimum critical current of 549A at 20K, far exceeding the nominal operating current of 150A (margin 2.7 times), providing redundancy for high-field steady-state operation.

In terms of structural optimization, a "soldered metal insulation (SMI)" architecture is adopted, balancing thermal conductivity and delamination resistance; the non-insulated design allows coils to bypass local defects through inter-turn resistance, achieving passive quench protection without additional hardware.

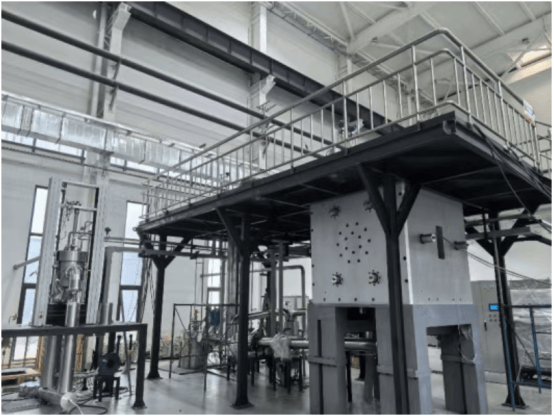

In terms of efficient manufacturing, a dedicated production line was developed, compressing the double pancake (DP) coil production cycle to within 3 days, and compatible with REBCO tape from 3 suppliers, verifying scaled production potential.

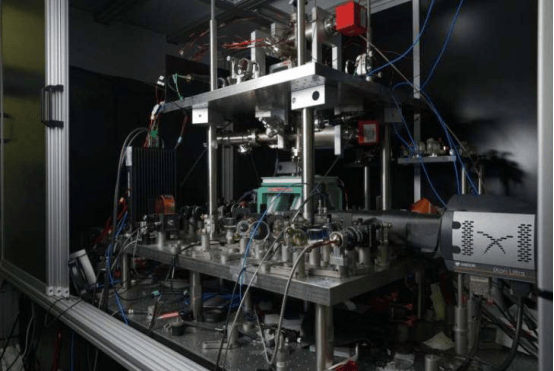

In a custom cryogenic test system (20K supercritical helium cooling, vacuum degree up to 1×10⁻⁵ torr), the Canis magnetic pixel array completed key validation: generating EOS1 and EOS2 magnetic field configurations related to Eos, corresponding to different curvature regions of the plasma edge; using LabVIEW real-time control system and ATLAS scanning technology, the measured magnetic field error at 25cm was only 0.56% (EOS1) and 0.60% (EOS2), far below the 1% target; Monte Carlo simulations showed that even considering sensor and coil position errors, the error in the 95% confidence interval was still ≤0.94%, with stability meeting fusion operation requirements.

Thea Energy stated that the Canis project validated the core value of high-temperature superconducting planar coils: compared to traditional schemes, lower manufacturing costs, shorter cycles, and scalability to large devices by increasing coil numbers. The next step is to test transient magnetic field control and quench protection, laying the foundation for Eos integration and Helios (fusion pilot device) scaling.