A new advanced steel designed to withstand the extreme conditions inside fusion energy reactors has shown swelling under high radiation levels during testing, indicating the need for further development. This finding comes from a series of studies led by engineers at the University of Michigan (UM).

Kevin Field, professor of nuclear engineering and radiological sciences at the University of Michigan and senior author of the study, stated: "These results represent the highest fidelity for fusion-relevant steels in radiation resistance and will guide alloy development and improve radiation effects models in the coming years."

Fusion energy, which generates power by combining light atoms, is seen as a cleaner and more sustainable alternative to fission. However, building fusion reactors poses enormous engineering challenges, as components must endure temperatures up to 600°C (1112°F) while resisting radiation damage and helium production, which can otherwise cause material swelling and deformation.

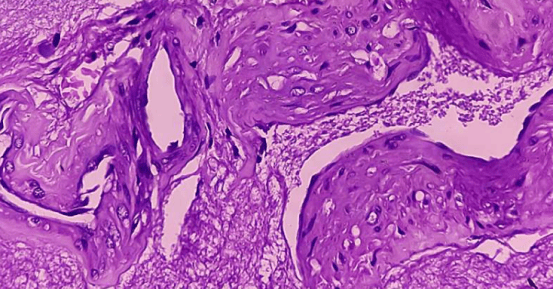

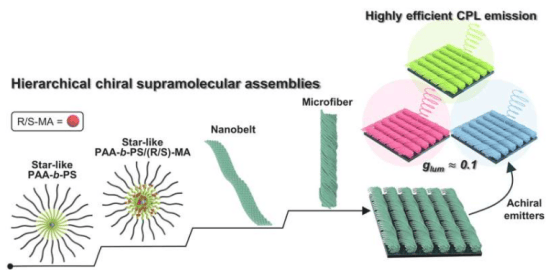

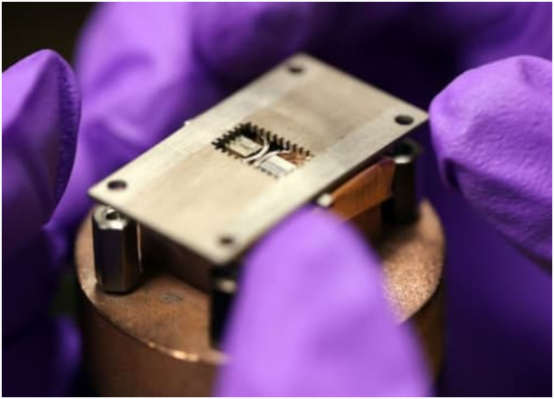

To address this, researchers have been developing reduced-activation ferritic/martensitic (RAFM) steels containing billions of nanoscale titanium carbide (TiC) precipitates, designed to trap helium produced in fusion reactions and prevent swelling. The University of Michigan team specifically tested a next-generation RAFM alloy—Castable Nanostructured Alloy #9 (CNA9).

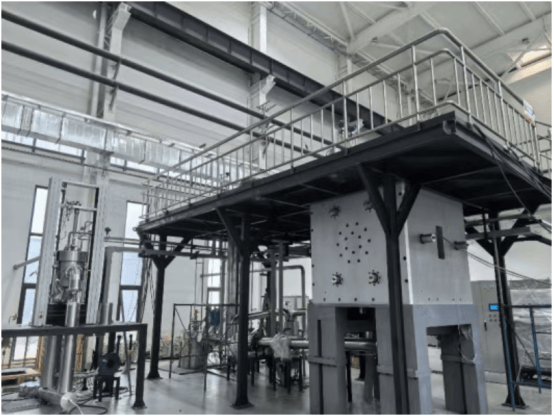

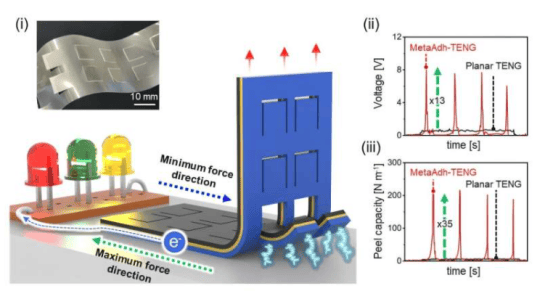

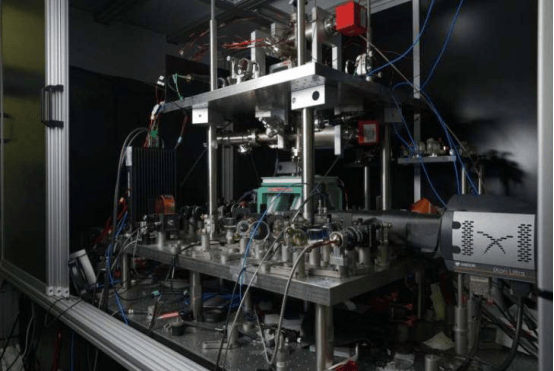

The research group employed a breakthrough method using a particle accelerator to bombard steel samples simultaneously with two ion beams—one causing radiation damage and the other introducing helium. This approach more accurately simulates conditions inside a fusion reactor than previous experiments testing these factors separately.

Tests revealed that TiC precipitates successfully trapped helium at lower radiation levels, but began dissolving at high damage levels (50 to 100 displacements per atom, or dpa). Once the particles dissolved, the alloy lost its ability to trap helium, resulting in significant 2% swelling. Kevin Field said: "The results at high radiation doses (>15dpa) were surprising; we expected the TiC precipitates to remain stable at the highest temperatures evaluated, but that was not the case."

The researchers described this discovery as one of the "highest fidelity results" for fusion-relevant steels, providing critical guidance for future alloy development. The team suggests increasing the density of TiC precipitates by 1,000 times to more effectively prevent swelling and recommends further ion beam testing to better simulate the complex environment of fusion reactors.

Lead author TM Kelsy Green emphasized: "This capability is essential for driving discoveries and optimizing materials to enable the deployment of future fusion energy."

Although fusion energy holds immense potential—using hydrogen isotopes from seawater with no risk of nuclear meltdown—the technology is not yet suitable for small power plants. Contributor Yang Ying concluded: "The dissolution of TiC precipitates at high radiation doses provides valuable guidance for future development work, highlighting the need for more stable TiC precipitates in CNA steel design."