Russian scientists have developed a promising cathode material for lithium/potassium batteries using a simple in-situ technique based on polyaniline and sulfur. The researchers involved in this study are from the Federal Research Center of Problems of Chemical Physics and Medicinal Chemistry of the Russian Academy of Sciences (Chernogolovka), the Ufa Federal Research Center of the Russian Academy of Sciences, Ufa State Petroleum Technological University, and the M.N. Mikheev Institute of Metal Physics of the Ural Branch of the Russian Academy of Sciences (Yekaterinburg). The research results have been published in the journal Synthetic Metals.

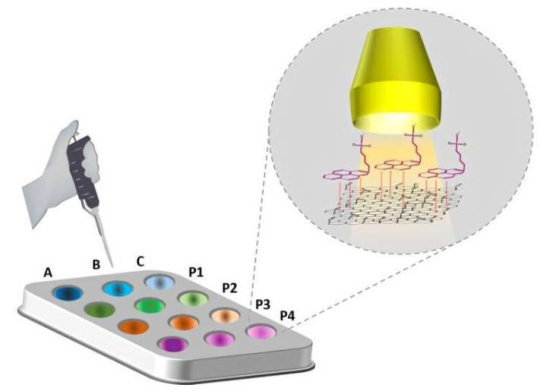

The experts have proposed a new simple method for producing cathode materials for lithium-ion and potassium-ion batteries, based on the conductive polymer polyaniline (PANI), multi-walled carbon nanotubes (MWCNT), and sulfur. The method relies on the in-situ chemical polymerization of aniline in the presence of MWCNT and ammonium persulfate, ensuring uniform distribution of components in the composite material. Sulfur nanoparticles are approximately 20nm in size, increasing their availability for electrochemical reactions. A lower sulfur content (up to 25wt%) avoids typical problems of conventional lithium-sulfur batteries, such as polysulfide dissolution and low conductivity.

The most promising PANI/MWCNT/S composite material containing 3–5% sulfur demonstrates a specific capacity of 165mAh/g at a current density of 100mA/g and an average discharge voltage of 2.4V, surpassing the corresponding values of pure polyaniline and its composites with sulfur-free nanotubes.

In addition to lithium batteries, the scientists have conducted preliminary tests of the developed composite cathode (based on polyaniline and its derivative polyanisidine) in potassium batteries for the first time, with a liquid potassium-sodium alloy (K-Na) used as the anode. These results open the way for exploring the possibilities of creating more economical and scalable batteries in the “post-lithium” era. The new method for producing organic electrode materials proposed in the study reduces the number of synthesis steps and lowers the cost of cathode production.