A research team from the Department of Chemistry at King's College London has recently achieved a major breakthrough by developing a revolutionary characterization technique for graphene oxide. Through an innovative "interactive fingerprinting" method, they have successfully addressed the key technical challenges hindering the commercial application of graphene oxide. The research results have been published in the latest issue of the Journal of the American Chemical Society, paving the way for the industrialization of graphene oxide in fields such as new energy and electronic devices.

Traditional characterization methods for graphene oxide mainly rely on high-end instruments such as X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy. Not only does a single test cost up to £5,000, but it also requires professional technicians to operate, with the entire analysis process often taking several weeks. This high technical threshold has severely restricted the transition of graphene oxide from laboratory to market. Dr. Andrew Thurman, the leader of the research team, pointed out: "For a long time, the biggest challenge in graphene oxide research has been batch-to-batch stability. Our new technology can complete the detection in just a few hours, at only one-tenth the cost of traditional methods."

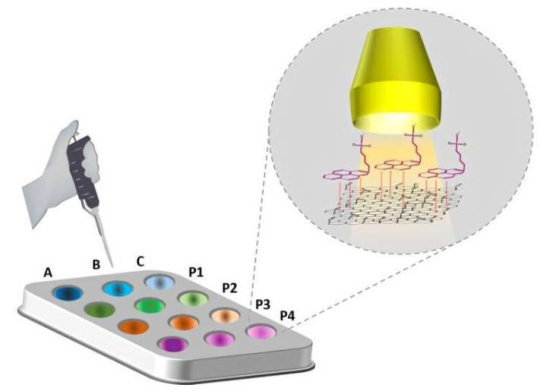

This breakthrough technique employs a unique molecular probe approach. The researchers designed a series of specific fluorescent molecular probes that selectively interact with different functional groups on the surface of graphene oxide. By monitoring changes in fluorescence signals and combining them with advanced mathematical modeling algorithms, a "molecular fingerprint" of the material can be quickly constructed. This method not only accurately determines key parameters such as oxygen content and layer number of graphene oxide but also intuitively reflects the material's uniformity and defect distribution.

"The greatest advantage of this technology lies in its universality and convenience," explained Dr. Ming Zhang, the first author of the paper. "The detection equipment we use consists of ordinary instruments commonly found in laboratories, allowing any research institution or company with basic analytical conditions to easily implement it." The research team has successfully applied this technology to the detection of multiple batches of graphene oxide samples, with results highly consistent with traditional methods, but reducing the detection time from several weeks to only 4-6 hours.

Even more exciting is the broad potential for expanding the application of this technology. The research team has confirmed that by adjusting the structure and properties of the molecular probes, the same method can be applied to the characterization of other two-dimensional materials, such as molybdenum disulfide and boron nitride. This provides strong technical support for the industrialization and development of the entire two-dimensional materials field.

Currently, the research team is collaborating with several material production companies and plans to convert this technology into a standardized detection protocol within the next year. Industry experts generally believe that this breakthrough will significantly lower the R&D and application barriers for graphene oxide, accelerating its commercialization in flexible electronics, new energy batteries, water treatment, and other fields.