A recent commentary in Nature Reviews Clean Technology is the first to propose a pathway for scaling decoupled water electrolysis (DWE) technology to produce industrial-scale green hydrogen.

Hydrogen is a key chemical feedstock, typically produced from fossil fuels with substantial CO₂ emissions. Using renewable electricity to electrolyze water produces oxygen instead of CO₂, offering a clean alternative. Industrial-scale green hydrogen production is one of the ultimate goals of the energy transition and could replace much of the world’s reliance on fossil fuels.

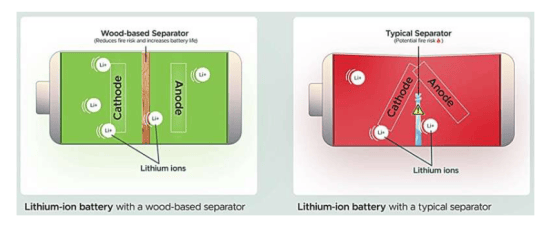

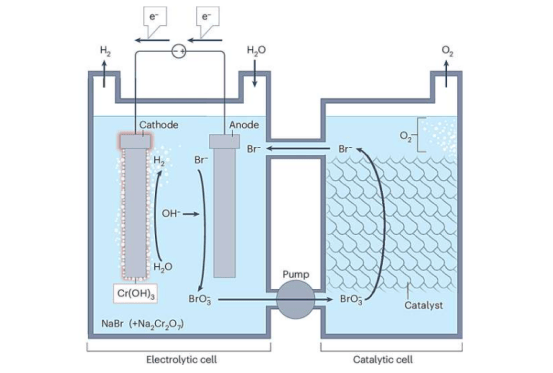

Conventional electrolysis uses a membrane-separated two-electrode system to split water into hydrogen and oxygen, but it suffers from high costs, risk of internal hydrogen crossover, and incompatibility with intermittent solar and wind power. DWE overcomes these issues by separating hydrogen and oxygen production in time or space, eliminating the need for a membrane and instead using redox-active materials that absorb and release ions to generate oxygen or hydrogen.

The commentary reviews various DWE approaches and is the first to outline a viable route for large-scale production. Authors include Professor Avner Rothschild (Technion – Israel Institute of Technology), Professor Mark D. Symes (University of Glasgow), Professor Jens Oluf Jensen (Technical University of Denmark), Dr. Tom Smolinka (Fraunhofer Institute for Solar Energy Systems), Rotem Arad and Gilad Yogev (H2Pro), postdoctoral researcher Dr. Guilin Ruan (Technion), and PhD student Fiona Todman (University of Glasgow), among other leading experts worldwide.

In 2013, Professor Mark Symes and colleagues at the University of Glasgow pioneered the original solution-phase redox-mediated decoupled electrolysis and have actively pursued its commercialization. In 2015, Professor Avner Rothschild and colleagues introduced a new technology using nickel-based redox electrodes, leading to the founding of H2Pro in 2019. Professors Jens Oluf Jensen and Dr. Tom Smolinka are electrolysis stack experts whose work provides insights into the challenges of scaling commercial electrolyzers, laying the foundation for comparing disruptive decoupled and membraneless electrolysis concepts. Rotem Arad and Gilad Yogev offer deep insights into translating the concept into large-scale green hydrogen technology.

This review is the first comprehensive presentation of feasible scaling strategies for DWE. Laboratory-scale DWE experiments produce less than one gram of hydrogen per day, while industrial systems require about one tonne per day—six orders of magnitude higher. Meeting current hydrogen demand would require approximately one million full-scale electrolyzers. Traditional industrial electrolyzers require stable grid power, limiting their applicability.

DWE’s unique advantage lies in its ability to store energy via redox-active materials, functioning like a built-in battery electrolyzer that buffers renewable energy fluctuations and is highly compatible with solar and wind systems—providing a critical pathway to low-cost, green renewable hydrogen production.

Scaling green hydrogen production will have massive impact. The current hydrogen market is worth about $250 billion annually; once industrial-scale production is achieved, the green hydrogen market is projected to reach $550 billion within a decade.

Professor Rothschild predicts that green hydrogen could account for 10% of the future energy market. Once produced at scale and sold at reasonable prices, it will replace most energy use in industry, heavy transport, and other sectors. Conventional electrolyzers should continue to evolve to adapt to the market, but DWE could become the “species” best suited to environmental changes.

Professor Symes explains that decoupled electrolysis technology is only about 12 years old, while conventional technologies like alkaline batteries and proton exchange membrane cells have been developed for decades or even centuries—providing context for the rapid scaling potential of the new decoupled systems. He expects decoupled electrolysis systems to become strong competitors to traditional electrolyzers over the next decade, particularly for converting renewable energy into green hydrogen.

The new ideas presented in the commentary are compelling and offer important insights into the long-term prospect of scaling DWE technology to benefit humanity.