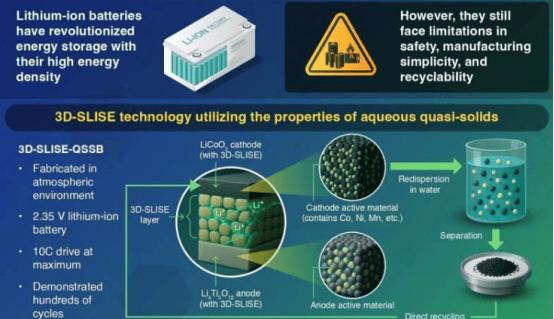

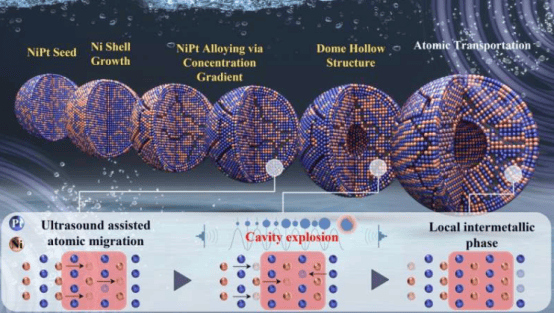

A Korean research team has developed an innovative catalyst technology for hydrogen fuel cells that significantly improves both activity and durability. Published in Advanced Materials, the findings are expected to reduce fuel cell system costs and extend service life.

The team led by Dr. Sung Jong Yoo at the Korea Institute of Science and Technology (KIST), in collaboration with multiple universities, synthesized platinum-nickel nano-catalysts with precise atomic arrangement at room temperature using an ultrasound-assisted method. Dr. Yoo stated: "This dome-shaped hollow-structured catalyst maintains high performance while greatly simplifying the preparation process."

Experimental data show that the new catalyst achieves a mass activity 7 times higher than commercial catalysts. In durability testing, it remained stable for over 42,000 hours—4.2 times longer than existing products. The researchers noted that this breakthrough can significantly extend maintenance intervals for large-scale fuel cell systems and reduce manufacturing costs by approximately 30%.

The technology is currently undergoing fuel cell stack-level evaluation and automotive application testing. The team is also exploring other transition metal combinations to further optimize hydrogen fuel cell performance.