A research team at the University of Chicago has developed a new artificial intelligence method that significantly enhances the efficiency of battery material development. This AI technology, utilizing an active learning model, requires only 58 experimental data points to explore millions of electrolyte combinations, opening new pathways for battery material research.

The team published their findings in Nature Communications, demonstrating how an AI model based on minimal data can accelerate the discovery process for battery materials. Postdoctoral researcher Ritesh Kumar from the Pritzker School of Molecular Engineering at the University of Chicago stated, "Each experiment takes weeks or even months to obtain a data point. Waiting to collect millions of data points to train these models is impractical." This AI method employs an experimental validation loop, feeding test results back into the model for continuous optimization.

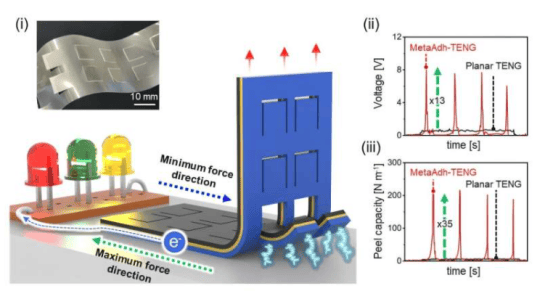

The researchers adopted a "trust but verify" strategy, conducting seven rounds of active learning, testing approximately ten electrolytes per round, and ultimately identifying four high-performing novel electrolyte solvents. Kumar noted, "The model isn’t very accurate initially, so there are predictions, but those predictions come with uncertainty." This AI-driven research approach effectively reduces experimental blind spots and avoids cognitive biases inherent in traditional research methods.

Co-first author Dr. Peiyuan Ma stated that the future application of AI in battery material development will shift toward generative approaches. Ma explained, "This means we are no longer limited to existing literature. In principle, the model can propose molecules that don’t exist in databases." The next phase of research will focus on developing AI systems capable of simultaneously evaluating multiple metrics, such as cycle life, safety, and cost, to advance battery material development toward practical applications.