Generative AI (GenAI) is demonstrating enormous potential in high-end equipment manufacturing, with particularly striking progress in robot design. Diffusion models like OpenAI's DALL-E, already valuable for human brainstorming, can now directly create functional robots. Recent diffusion-based approaches can generate robot structures and their control systems from scratch—with or without user input—and simulate and evaluate designs before fabrication.

Researchers at MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a new method that applies generative techniques to improve human-designed robots. Users sketch a 3D robot model, specify which parts they want the diffusion model to modify, and provide dimensions. The GenAI then brainstorms optimal shapes for those regions and tests them in simulation. Once a suitable design is found, it can be directly 3D-printed into a working physical robot—no further adjustments required.

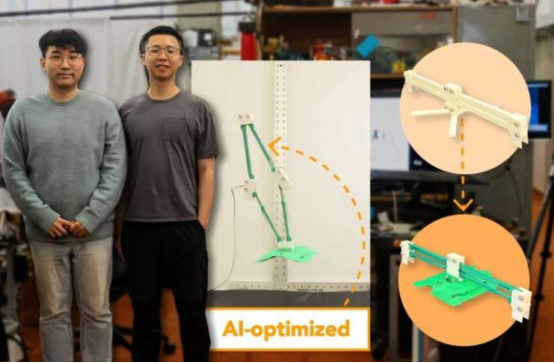

Robots built using this method achieved an average jump height of ~2 feet (6m)—41% higher than comparable robots the team designed manually. The two machines look nearly identical: both are made of PLA plastic, start flat, and spring into a diamond shape when a motor pulls cables. However, the AI-generated robot has curved links resembling thick drumsticks, while the standard version has straight, rectangular connectors.

To improve the jumping robot, the researchers sampled 500 potential designs from an initial embedding vector, selected the top 12 based on simulated performance to refine the embedding, and repeated this process five times—progressively guiding the AI toward better designs. The final design resembled a sphere and indeed delivered superior jumping ability.

Co-lead author and CSAIL postdoctoral researcher Byungchul Kim explained that the advantage of diffusion models lies in finding unconventional solutions. For example, to jump higher, the team considered thinning links to reduce weight—but 3D-printable material would become too brittle. The diffusion model proposed unique shapes that store more energy before the jump while avoiding overly thin links, helping researchers better understand the underlying physics.

Next, the team tasked the system with optimizing feet for safe landings. After repeating the optimization process and selecting the best performer, the AI-designed feet reduced falls by 84% compared to the baseline.

By enhancing both jumping and landing capabilities, diffusion models show promise for improving other robotic designs. Manufacturing or consumer-robotics companies could use this approach to refine prototypes and save engineers countless iteration hours.

To create a robot that jumps high yet lands stably, the researchers balanced the two objectives numerically, training the system to find the optimal trade-off between jump height and landing success rate across embedding vectors, ultimately producing the best 3D structure.

While the AI-assisted robot outperformed its human-designed counterpart, the researchers note room for improvement. This iteration used 3D-printer-compatible materials; future versions will employ lighter materials to achieve even greater heights.

Co-lead author and CSAIL Ph.D. student Tsun-Hsuan "Johnson" Wang said the project marks the beginning of using generative AI for novel robot design, with plans to expand to more flexible goals—such as using natural language to guide diffusion models in designing robots that can pick up a cup or operate a drill.

Kim added that diffusion models can also help generate joints, conceive component connections, and further increase jump height. The team is exploring adding more motors to control jump direction and improve landing stability.