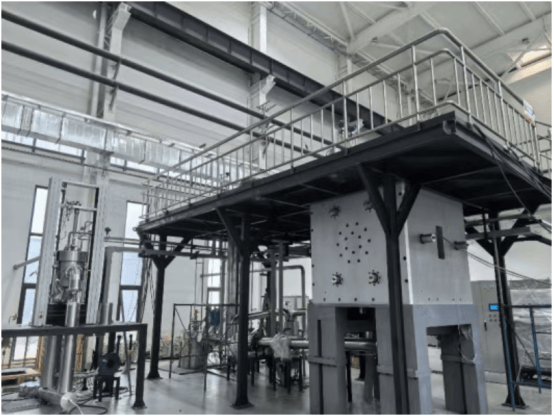

A research team at MIT has developed a fully autonomous experimental platform for efficiently screening high-performance polymer blends. The results, published in the journal Matter, demonstrate the application potential of combining artificial intelligence and robotics in materials science.

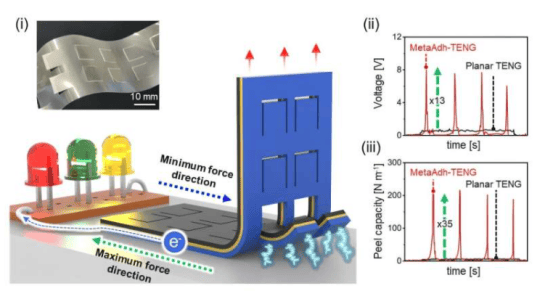

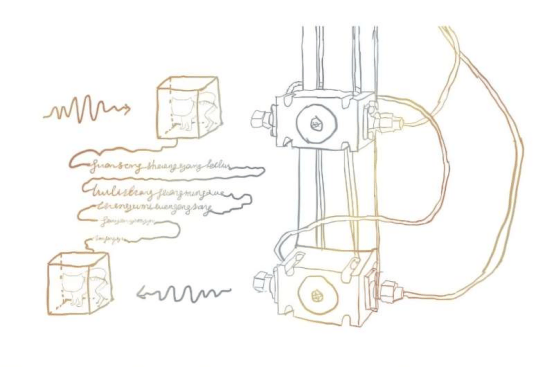

Polymer blends acquire new properties by mixing existing polymers, but traditional methods are inefficient due to the vast number of combinations and complex interactions. The new platform employs a closed-loop workflow in which an algorithm autonomously designs experiments, a robotic system performs mixing and testing, and subsequent experiments are optimized based on results. In testing, the system successfully screened hundreds of blends outperforming individual polymers, with the optimal blend retaining 18% higher enzyme activity than its components.

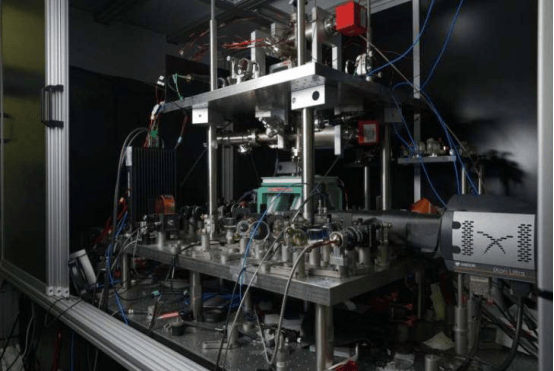

Senior author Connor Coley stated: "Algorithmic optimization covers the entire design space, avoiding missing key combinations." The study also found that high-performance blends do not necessarily rely on high-performance single components, validating the importance of comprehensive exploration. The team tuned a genetic algorithm to balance random exploration and directed optimization while solving technical challenges in robotic operations, such as temperature uniformity and liquid-handling precision.

The platform can complete 700 experiments per day, dramatically shortening R&D cycles. In the future, this approach may be extended to plastics, battery electrolytes, and other fields. The team plans to further optimize the algorithm, improve data utilization efficiency, and simplify automated operation workflows.