A study from the University of Johannesburg shows that a promising industrial process—Sorption-Enhanced Chemical Looping Gasification (SECLG)—can efficiently convert crushed sugarcane waste into green hydrogen, with efficiency far exceeding previous expectations. The findings were published in Renewable Energy.

Simulation results indicate that the SECLG process is more energy-efficient than traditional biomass gasification plants, with significantly reduced emissions of tar, carbon monoxide, carbon dioxide, and nitrogen. In the future, it could help decarbonize energy-intensive industries such as steel and cement.

Globally, approximately 1.4 billion tons of sugarcane are produced annually, generating about 540 million tons of bagasse. Countries like India, China, Brazil, and Mauritius already use bagasse gasification for power generation. Gasification chemically "burns" biomass to produce syngas (a clean mixture of hydrogen and other gases) without traditional combustion.

Professor Bilainu Oboirien from the Department of Chemical Engineering Technology at the University of Johannesburg noted that current large-scale gasification methods suffer from low energy efficiency, low hydrogen yield, and high production of tar and other harmful byproducts. Typical biomass gasification produces complex syngas compositions, with uncaptured CO₂ and high tar yields requiring extensive additional cleaning equipment, increasing operational costs.

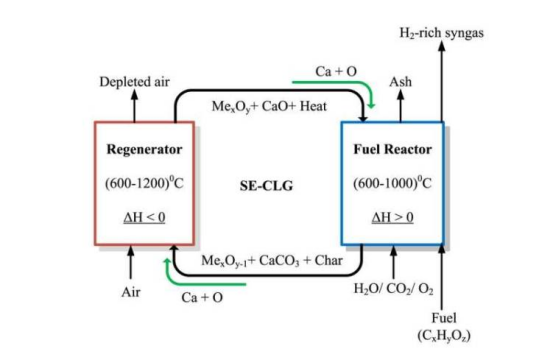

The SECLG process is more effective. Over the past decade, multiple research groups have been developing it. Compared to existing industrial methods, SECLG can produce higher-purity green hydrogen, achieve higher biomass yields, offer greater energy efficiency, and better capture carbon during production.

Professor Oboirien and master's candidate Lebohang Gerald Motsoeneng created a mathematical model of the SECLG process and conducted comprehensive simulations on a laboratory scale using Aspen Plus software. They compared the effects of two oxygen carriers—nickel oxide (NiO) and iron oxide (Fe₂O₃)—on parameters like hydrogen yield. The model showed that SECLG-produced gas had hydrogen content of 62–69%, carbon monoxide 5–10%, carbon dioxide less than 1%, tar less than 1g/Nm³, and nitrogen less than 5%. The higher hydrogen yield, lower tar concentration, and reduced nitrogen dilution can significantly lower economic costs. However, hydrogen still requires further purification to meet industrial-grade gas standards.

Oboirien stated that countries with existing biomass gasification infrastructure and easy access to biomass—such as China, Brazil, and South Africa—will benefit most from SECLG green hydrogen production from sugarcane bagasse, as retrofitting existing technology is easier and less costly than building dedicated new plants.

The Aspen Plus model also examined the stability of oxygen carrier and sorbent materials. Results showed that nickel oxide produces higher-purity hydrogen and more effectively captures CO₂, while iron oxide excels at producing more combustible mixed gases, indicating that a tunable SECLG process could produce transportation fuels like diesel in addition to hydrogen.

Currently, the model has not addressed degradation of oxygen carrier and sorbent materials over time, nor modeled or simulated solid material transport and effective separation of ash and char, which are critical for viable SECLG systems. Oboirien said experiments are ongoing in the laboratory to further validate the concept and verify the model based on experimental data.

Although SECLG has been validated through process simulation models, it has not yet been applied to large-scale industrial biofuel-to-syngas production. The process requires temperatures around 600°C, pressures about 5 bar, multiple cycles, and transport systems for metal oxide oxygen carriers and sorbents to achieve continuous catalysis and carbon capture cycles. Oboirien believes sorption-enhanced biomass chemical looping gasification is a promising process for producing hydrogen and transportation fuels, and realizing its potential requires infrastructure investment and strengthened industry collaboration.