Wedoany.com Report-Oct 09,Natel’s mission remains focused on supporting healthy rivers, promoting biodiversity and decarbonising the grid and helping modernise the global hydropower fleet in a way that balances energy production with ecological health.

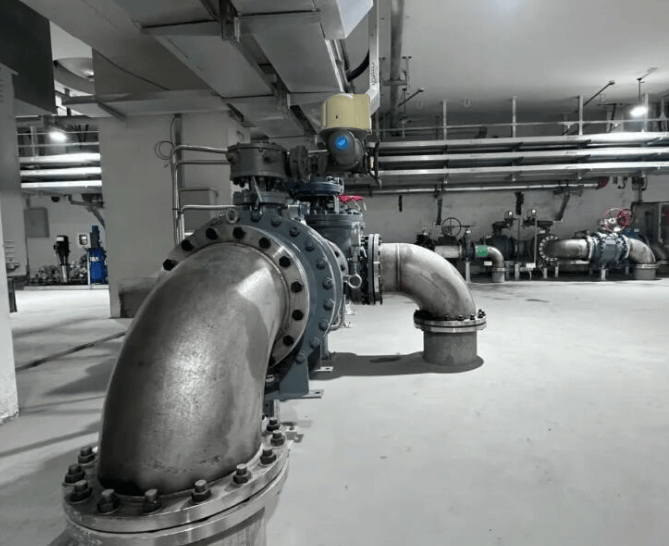

Looking at North America specifically, we know that one of the key challenges facing the North American hydropower fleet is that nearly 80% of the fleet operates in settings where the high volumes of water flowing through hydropower sites makes conventional fish protection measures, like fine exclusion screens, difficult and costly to install, operate, and maintain. The only other conventional methods to improve fish passage, such as rerouting fish or plant shutdowns during migration reduce power output and add complexity without fully addressing the risks posed by conventional turbines.

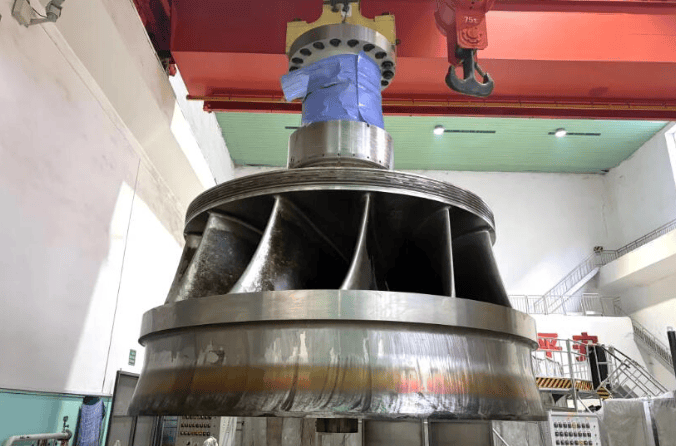

We’re incredibly proud that our Natel FishSafe turbine designs are the only turbine blade designs applicable to all major medium and low head turbine configurations at sites with up to 40m of hydraulic head, delivering uncompromising performance (designs with efficiency up to 94%), safe fish passage (demonstrated survival rates between 98-100%) and are readily customizable to fit into existing plant civil works.

Beyond cost savings, FishSafe turbines can also boost power generation by up to 10% by modernizing aging equipment, minimizing head losses associated with screening and potentially eliminating the need for bypass flows. Increased power generation not only enhances revenue potential but also improves operational flexibility, which is crucial for adapting to fluctuating demand and maintaining grid stability.

To date, Natel’s FishSafe turbines have generated 3.25GWh of renewable electricity and are in operation in the US and in Europe. In addition, Natel conducts research and development including CFD modelling and analysis to improve fish safety at the plant level and performance and fish passage scale model testing at the company’s hydraulic test facility. Natel also has a field test site at a 300kW project that it owns and operates in Oregon.