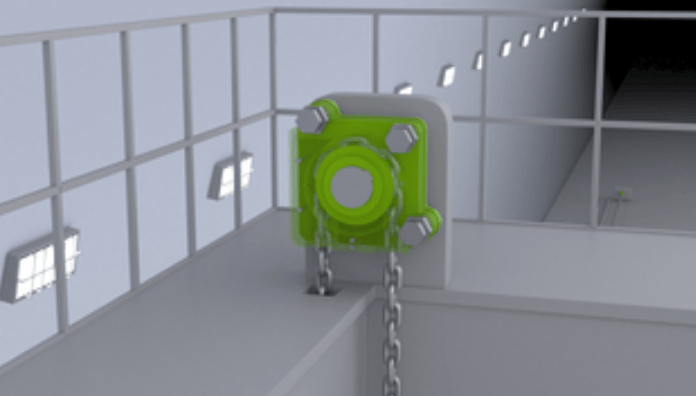

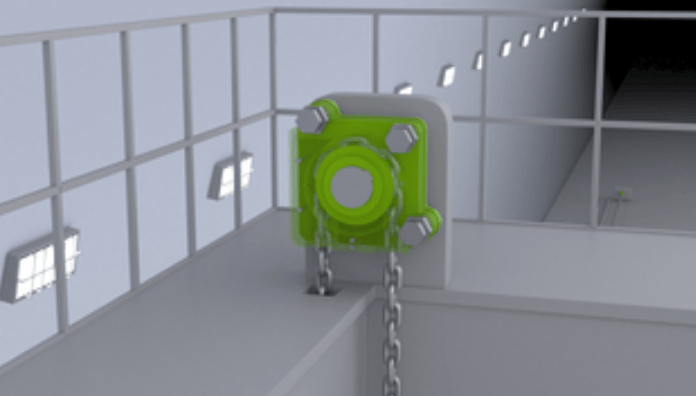

Wedoany.com Report on Feb 15th, In tunnel construction, space limitations are a common challenge. The RUD Tecdos drive system, with its compact components and drive housing design, can be installed directly on-site, effectively addressing this issue. Sascha Olfert, Business Development Manager at RUD, stated: "Traditional cable drives often require large cable winches and multiple deflection devices, whereas the Tecdos drive system eliminates these needs because the chain can deflect in tight spaces and is stored in a chain bag that occupies minimal space."

The RUD Tecdos drive system offers a diverse range of products and solutions for tunnel engineering, including sprockets, lifting limiters, slings, and complete systems such as the Tecdos Pi-Gamma and Tecdos Omega Drive. The Tecdos Pi-Gamma is a flexible 2-in-1 chain drive system suitable for vertical and horizontal applications, featuring fixed 180° or flexible 90° to 180° chain deflection, which enhances construction efficiency. Different versions can provide pulling forces of up to 260 kN.

The Tecdos Omega Drive system supports linear or rotational movements in tunnel construction, featuring a 180° wrap angle design. It can be attached to the load or moving chain depending on the application, with standard variants also generating a pulling force of 260 kN per drive.

In tunnel construction, RUD Tecdos drive technology is widely used in lifting equipment, such as hoisting heavy machinery to the tunnel ceiling or operating vertical drilling rigs. Its robustness also makes it suitable for applications like curve drives, belt storage systems, conveyor belts, transport trolleys, and transport racks. It can also be used in cutting equipment, rebar cranes, and shaft lowering systems.

Olfert added: "The Tecdos drive system can handle weights of up to 25 tons, with theoretically no upper limit. If larger loads need to be moved, this can be achieved by increasing the number of drives."