Aduro Clean Technologies has officially transitioned its Next Generation Process (NGP) pilot plant into initial operations, marking a significant step in the company's path toward commercializing its chemical recycling technology.

This move indicates Aduro is shifting from commissioning to full operational testing to support research, customer collaboration, and feedstock qualification efforts. The NGP pilot plant now operates as an integrated process unit, generating critical performance and environmental data under real-world conditions, providing an empirical foundation for the commercialization of chemical recycling technology.

Ofer Vicus, CEO of Aduro, stated: "This milestone reflects the rigorous execution across our engineering, operations, and project delivery teams."

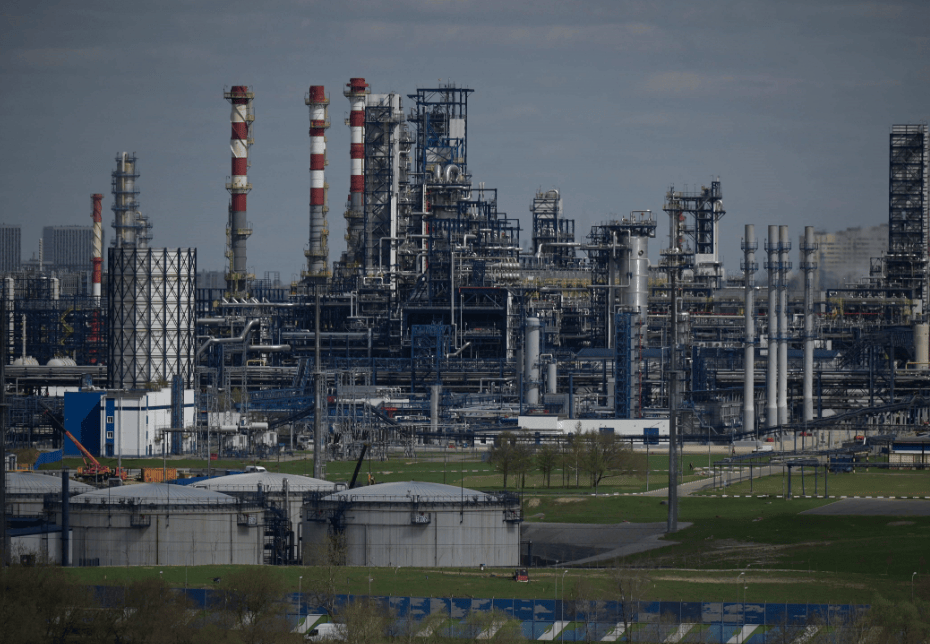

"As the NGP pilot plant enters a structured testing operation, it becomes a key asset for advancing our commercialization path and deepening stakeholder engagement. The site for the First-of-a-Kind (FOAK) facility has been selected, and work underway in London will directly guide design and integration planning, enhancing the company's readiness to execute the next phase of scale-up."

The pilot plant serves as a bridge between laboratory development and Aduro's first-of-a-kind industrial facility. Site selection for the FOAK plant is complete, and equipment evaluation is ongoing to guide design and procurement decisions.

David Weizenbach, COO of Aduro, said: "Following commissioning, our focus has shifted to operating the integrated system and learning from it."

"The NGP pilot plant expands on the work completed in the R2 continuous flow reactor, allowing us to evaluate mixed waste plastic samples from customer programs and other real-world sources over longer durations and under more integrated operating conditions. These activities aim to optimize operational parameters to achieve optimal yield and consistent performance from variable feedstocks, while validating design assumptions for the FOAK industrial plant."

Aduro's NGP pilot plant utilizes industrial-grade automation and control systems provided by Siemens, enabling repeatable operations, high-resolution data collection, and scalable process control. The operations and technical teams have completed extensive training, achieving full operational readiness for expanded testing activities.

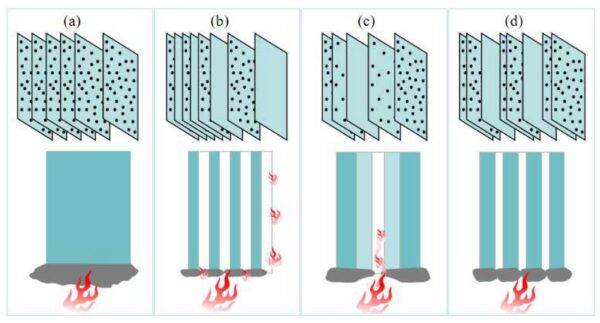

The company's patented Hydrochemolytic™ technology uses an aqueous chemical process to convert waste plastics, heavy crude oil, and renewable oils into higher-value products at lower temperatures and costs. Aduro aims to transform low-value feedstocks into sustainable resources, supporting the commercialization of chemical recycling technology.

With the NGP pilot plant in operation, Aduro is poised to generate the data needed to optimize the process, support commercialization, and advance the development of its FOAK facility, further driving the commercialization of chemical recycling technology.