The Swiss aluminum product specialist Allucan AG, based in Bremgarten, focuses on producing prototypes and custom components for industries such as railways, power, shipbuilding, and aviation. The company manufactures lightweight aluminum transformer housings and special enclosures primarily used in high-performance locomotives and high-speed trains. These products have stringent safety requirements, necessitating welds with precise geometric shapes and consistent layered structures, sometimes involving over 20 layers depending on material thickness.

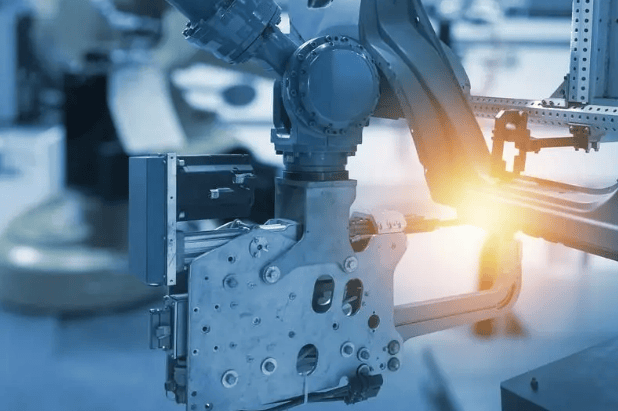

During the welding process, welders typically use Gas Tungsten Arc Welding (GTAW or TIG) to create smooth weld beads that provide support for subsequent layers. Smooth welds help reduce notch effects, thereby enhancing the structural integrity of the welded joint. For thicker materials, Gas Metal Arc Welding (GMAW or MIG) is used to build up layers, offering higher welding speeds and good process control.

Allucan AG's welders are equipped with Fronius's iWave AC/DC Pro 500i multi-process welding system. With simple operation, they can quickly switch between TIG and MIG. CEO Markus Jäger states: "This flexibility—especially in terms of saving working time and optimizing space utilization—provides us with significant advantages."

The multi-process welding system integrates the CycleTIG function, which effectively controls heat input and arc stability. The RPI (Reverse Polarity Ignition) automatic intelligent ignition feature ensures fast and repeatable ignition processes without the need for manual parameter adjustments based on material properties. Additionally, the built-in authorization management system allows supervisors to set personalized access rights for each welder. When logging in with a key card or key fob, near-field communication technology instantly identifies the corresponding permissions.

During TIG welding, the automatic post-flow gas function protects the tungsten electrode. The software calculates the post-flow time based on preset welding current and electrode diameter. The sealed welding torch design enables efficient cooling, and its sidewall structure helps maintain arc stability. Jäger further explains: "Component accessibility is one of our key concerns. The variable contact tip length welding torch provided by Fronius allows welders to access components more conveniently. This flexibility in torch length is crucial, ensuring precise and high-quality welds even in hard-to-reach areas."