Recently, scientists from the Krasnoyarsk Scientific Center of the Siberian Branch of the Russian Academy of Sciences, together with colleagues from Russia, Mongolia, and China, proposed a technology for processing coal into polycyclic aromatic hydrocarbons and resins. The related research results were published in the journal Materials.

This technology can convert up to 97.5% of coal into valuable raw materials, minimizing waste volume and significantly reducing the content of the carcinogen benzo[a]pyrene. It opens new prospects for the coal industry, providing a more environmentally friendly alternative to traditional combustion, with the resulting materials usable for producing carbon fiber, electrode coke, and other high-tech products.

In recent years, the global oil industry has faced the issue of an increasing proportion of heavy, high-sulfur crude oil, which is costly to process and refine. At the same time, due to declining demand for metallurgical coke, coal tar production has decreased, and its environmental safety is questionable due to high content of carcinogenic compounds (such as benzo[a]pyrene). Against this backdrop, the production of modern carbon materials has seen growing demand for new raw materials, making coal chemical processing one of the promising solutions.

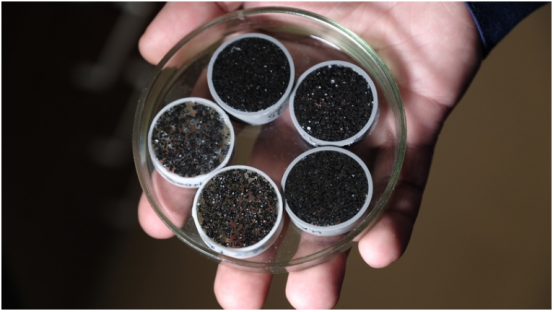

The coal processing technology proposed by this international research team can convert coal into valuable liquid products and resins. The process involves dissolving coal in a special liquid extracted from coal or petroleum, with experts testing the effects of coal tar, petroleum diesel, and their mixtures as solvents. When heated to about 380°C and under the action of the solvent, the coal is broken down, and the final product is a polycyclic aromatic hydrocarbon concentrate with a yield of up to 97.5%.

The scientists pointed out that the solvent affects the properties of the final product, with the main difference being aromaticity; higher aromaticity leads to greater heat resistance and chemical stability of the resulting materials, which is crucial for carbon composite production. Materials prepared using coal tar have the highest aromaticity and are particularly valuable for the chemical industry.

The main advantage of this technology is the reduction in harmful compound content in the resulting substances, particularly the concentration of benzo[a]pyrene (one of the most dangerous carcinogens), which is significantly lower than in traditional coal tar pitch. The study also found that extending the coal dissolution time can further reduce carcinogen content, making the new technology not only effective but also safer from an environmental perspective.

This R&D achievement improves coal utilization efficiency and provides an alternative to coal combustion. By converting coal into valuable compounds with minimal waste—less than 8% regardless of the solvent chosen—it significantly reduces unused residues and lowers the emission of harmful substances into the environment.

These developments can lay the foundation for planned research and production parks in the region, with the integration of basic research and industrial enterprises accelerating the implementation of coal processing technology.

One of the study's authors, Chief Researcher at the Institute of Chemistry and Chemical Technology of the Siberian Branch of the Russian Academy of Sciences and Doctor of Chemical Sciences Peter Kuznetsov, stated: "The substances obtained during low-temperature coal processing can serve as the basis for manufacturing modern high-tech carbon materials with lower carcinogenicity. They contain fewer harmful substances and have structures suitable for various industrial applications. Depending on the solvent, the properties of the resulting raw materials can be controlled. For example, products containing coking resin solvents are very suitable for producing needle coke—a material important for high-strength carbon electrodes, batteries, and nuclear energy. Products containing oil solvents can be used for carbon fiber production. Our technology requires no catalysts or hydrogen, operates under mild conditions, and can process coal almost completely. This makes it promising for replacing some petroleum raw materials and developing more environmentally friendly carbon material production methods."

The study was funded by the Russian Science Foundation (grant number 24-43-03001) and the Mongolian Foundation for Science and Technology, with the relevant materials prepared under the "Decade of Science and Technology" framework of the Russian Ministry of Education and Science through grants.