A research team affiliated with Ulsan National Institute of Science and Technology (UNIST) in South Korea has introduced a cutting-edge modular artificial leaf that simultaneously meets the requirements for high efficiency, long-term stability, and scalability, marking a significant step forward in green hydrogen production technology essential for achieving carbon neutrality.

The innovative system, led by Professors Jae Sung Lee, Sang Il Seok, and Ji-Wook Jang from the School of Energy and Chemical Engineering, mimics natural leaves by producing hydrogen gas using only sunlight and water, without requiring an external power source, and without emitting carbon dioxide during the process—this is a clean method of hydrogen production. The research was published in the journal Nature Communications.

Unlike traditional photovoltaic-electrochemical (PV-EC) systems (which generate electricity first and then produce hydrogen), this method directly converts solar energy into chemical energy, reducing losses associated with resistance and minimizing the installation footprint. However, challenges related to low efficiency, durability, and scalability have previously hindered its commercial deployment.

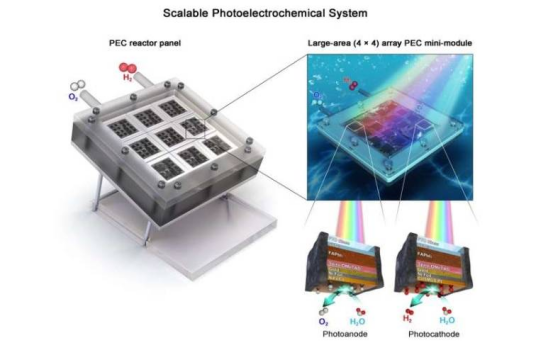

To address these issues, the research team utilized a chlorine-doped formamidinium lead triiodide (Cl:FAPbI₃) absorber layer and a UV-insensitive tin oxide (Cl:SnO₂) electron transport layer to fabricate high-performance 1cm² perovskite-based photoelectrodes. These units were assembled into a 4×4 array to construct a scalable modular system capable of stably producing hydrogen using only sunlight.

Notably, the entire module achieved a solar-to-hydrogen conversion efficiency of 11.2% under unbiased single-sun illumination—surpassing the 10% threshold widely regarded as the benchmark for commercial viability.

The team attributes this high performance and stability to the strategic combination of chlorine-doped perovskite absorbers, UV-resistant electron transport layers, and nickel-iron-cobalt (NiFeCo) catalysts. To ensure durability, they employed specialized nickel foil and resin encapsulation techniques, enabling the device to operate continuously for 140 hours while maintaining 99% of its initial performance.

Professor Jae Sung Lee emphasized: "This achievement goes beyond laboratory-scale demonstrations, with component-level efficiency exceeding 10%, which is a key milestone toward practical applications." He further added: "The artificial leaf can be scaled up to larger panels similar to photovoltaic modules, marking a decisive step toward commercial deployment."