Recently, researchers from Purdue University, in collaboration with LightSpeed Studios, have introduced an innovative technology that generates robot inspection plans based on written descriptions, opening new pathways for robotic applications in the real world. This advancement promises to make robot inspections in various complex environments more efficient and accurate.

In the field of robotics, while robots are widely used in product manufacturing, packaging, and minimally invasive surgery, most infrastructure and environmental inspections still rely on human labor. To address this, the Purdue University research team has focused on developing a computational model capable of generating inspection plans based on specific requirements.

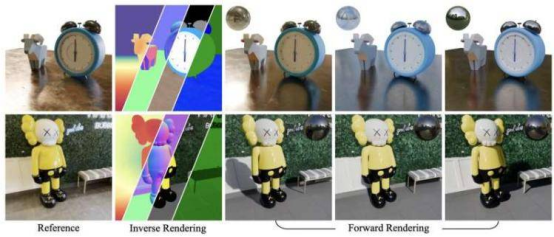

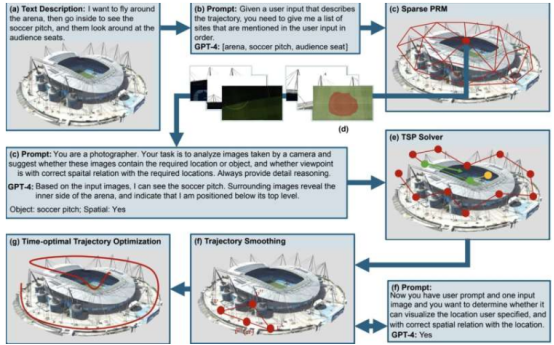

The team's proposed method is based on a vision-language model (VLM) that processes both images and written text simultaneously, enabling precise planning of robot inspection trajectories. First author Sun Xingpeng stated: "Our research is inspired by real-world challenges in automated inspection, aiming to develop a model that efficiently generates task-specific inspection routes."

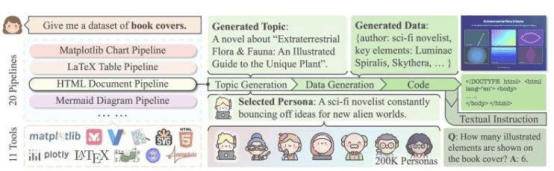

Unlike traditional machine learning-based generative models, the team's approach does not require further fine-tuning the VLM on large datasets. Instead, it leverages pre-trained VLMs (such as GPT-4o) to interpret inspection objectives described in natural language and related images. Candidate viewpoints are evaluated through semantic alignment, and GPT-4o is used for multi-view image reasoning to ultimately generate optimized 3D inspection trajectories.

In testing, the model successfully outlined smooth trajectories and optimal camera viewpoints for completing required inspections in various real-world environments, predicting spatial relationships with over 90% accuracy. These results demonstrate the model’s significant advantages in robot inspection planning.

The research team stated that their next steps include extending the method to more complex 3D scenes, integrating active visual feedback to dynamically refine plans, and combining the technology with robot control to achieve closed-loop physical inspection deployment. This will provide broader opportunities for robotic applications in the real world.