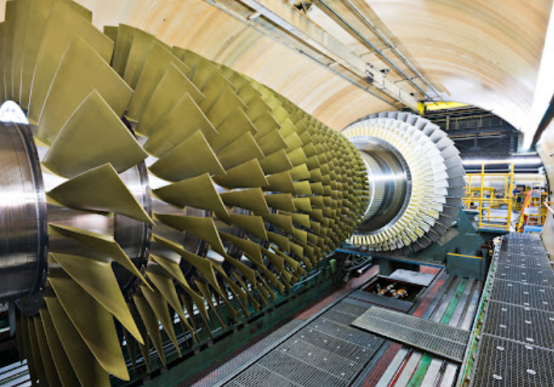

According to TASS on July 15, scientists at the National Technical Initiative (NTI) Competence Center of Novosibirsk State University have developed a method for repairing gas turbine engine blades. The technology has been patented and is being promoted for industrial application.

Citing senior researcher Alexander Malikov from the NTI Center, the university's press office reported that the new method can repair severely worn parts of gas turbine blades while fully preserving the original performance characteristics of the product. The method uses a special mode of periodic laser pulses to form a strong protective layer of metal or ceramic composite material on the blade surface.

Traditional surfacing methods cause overheating in sensitive areas of the component, whereas the new method forms a protective layer before the main stage, maintaining the blade's geometry while ensuring strong adhesion between the repair material and the base. The technology reduces maintenance costs and extends the service life of gas turbine units used in aviation, energy, and natural gas transportation infrastructure. Previously, Russia partially relied on foreign technologies in this field.

Malikov noted that turbine blade production is one of the world's top ten critical technologies, currently mastered by only four countries: the United States, the United Kingdom, France, and Russia. In the context of foreign companies withdrawing, introducing domestic solutions is crucial for achieving industrial independence. The research used synchrotron radiation technology to analyze the phase composition of materials. Future experiments will continue at the Siberian Ring Photon Source, with a series of dedicated studies planned.