Recycled glass has the potential to become a major building material, opening new paths for environmentally friendly construction materials and sustainable development.

A recent study published in Explore Civil Engineering tested the feasibility of using powdered recycled glass as a stabilizer for compressed earth blocks. Compressed earth blocks are made by mixing soil with water and compressing it under high pressure, typically requiring cement for reinforcement. Scientists from the University of Portsmouth and others discovered that mixing recycled glass with lime and significantly reducing cement usage can achieve reliable stabilization effects.

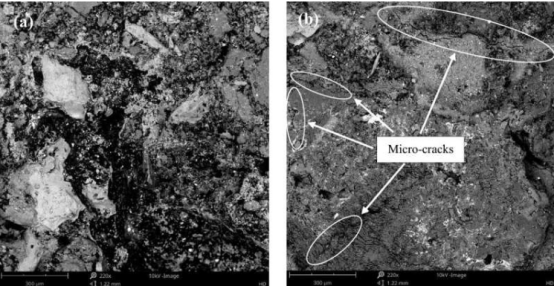

In the tests, the researchers mixed recycled waste glass particles (RWGP) at ratios of 0 to 25% to create compressed earth blocks. In addition to measuring mechanical properties, they used electron microscopy to examine the microstructural characteristics of the blocks after 28 days.

Co-author Dr. Muhammad Ali, Associate Professor of Materials and Environmental Innovation at the University of Portsmouth's School of Civil Engineering and Surveying, stated that due to the growing demand for using recycled industrial waste as sustainable building and construction materials, they hoped to evaluate the performance of compressed earth blocks with recycled glass particles.

Dr. Ali explained that at each percentage level, the team tested water absorption, the blocks' resistance to crushing under compression, and the maximum stress the blocks could withstand when stretched or pulled before fracturing or deforming. Tests found that blocks made with a mixture of 10% lime and 10% recycled glass particles were the strongest, resisting cracking under significant pressure.

In specific data, when the admixture was 10% recycled waste glass particles (RWGP) and 10% lime in compressed earth blocks (CEB), the compressive strength reached a maximum of 5.77MPa (megapascals, unit of pressure), compared to only 3.03MPa for unreinforced specimens after 28 days of curing—an increase of about 90%. In another related test, the same admixture yielded a maximum compressive strength of 0.52MPa, compared to 0.40MPa for unreinforced specimens after 28 days—an increase of 30%.

Microstructural analysis showed no visible cracks in the 10% RWGP and lime mixture, while microcracks appeared in the 25% RWGP and lime mixture. Future research will evaluate the thermal performance and durability of these more environmentally friendly building materials.