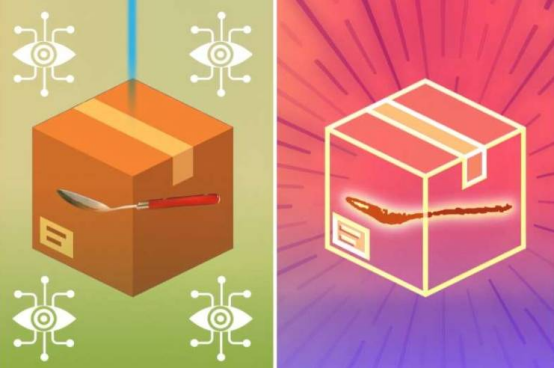

Researchers at the Massachusetts Institute of Technology have developed a new imaging technology called mmNorm, which utilizes millimeter-wave (mmWave) signals (the same type as Wi-Fi signals), bringing revolutionary breakthroughs to warehouse quality control robots and robotics applications in various high-end equipment manufacturing scenarios. With this technology, robots can penetrate obstacles such as cardboard shipping boxes to accurately detect defects in items buried under packaging foam, such as a broken handle on a cup, greatly improving detection accuracy and efficiency.

The mmNorm system transmits millimeter-wave signals that penetrate common obstacles like plastic containers and interior walls, receiving signals reflected by hidden objects. The system then inputs these reflected signals into an algorithm to precisely estimate the object's surface shape, achieving 3D reconstruction of line-of-sight obstructed objects. Research shows that this technology achieves reconstruction accuracy of up to 96% for a range of everyday items with complex curved shapes (such as silverware and power drills), far surpassing the 78% accuracy of the most advanced baseline methods, without requiring additional bandwidth, demonstrating extremely high application value.

In the field of high-end equipment manufacturing, mmNorm technology has broad application prospects. For example, in factory environments, robots can use this technology to distinguish tools hidden in drawers and accurately identify their handles for more effective grasping and manipulation, avoiding damage. Additionally, the technology can be combined with augmented reality headsets, allowing factory workers to see realistic images of completely occluded objects, improving operational precision and safety.

Traditional radar technology can detect hidden or distant objects through back-projection, but for small objects that robots may need to identify (such as kitchen utensils), the image resolution is too coarse. During the development of mmNorm, MIT researchers broke through traditional thinking by discovering and utilizing the important property of specular reflection. They developed the mmNorm algorithm, estimating surface normals (the direction of the surface at a specific point in space) and combining special mathematical formulas to achieve high-precision 3D reconstruction of objects.

To verify the effectiveness of mmNorm technology, the researchers created a prototype system connecting radar to a robotic arm. The arm continuously takes measurements while moving around hidden objects, and the system estimates the curvature of the object's surface by comparing signal strengths received at different positions. Test results showed that mmNorm reduced reconstruction error by about 40% compared to the most advanced methods when reconstructing more than 60 complex-shaped objects (such as cup handles and curves), while also more accurately estimating object positions.

Furthermore, mmNorm technology can distinguish multiple objects, such as forks, knives, and spoons hidden in the same box, and performs well on objects of various materials (including wood, metal, plastic, rubber, glass, and combinations of multiple materials). However, the technology does not work for objects hidden behind metal or thick walls.

The MIT research team stated that they will continue to explore potential applications of mmNorm technology and hope to improve its resolution in future work, enhancing imaging performance for objects with low reflectivity and allowing millimeter waves to more effectively penetrate thicker obstructions for imaging. This research not only represents a paradigm shift in signal processing and 3D reconstruction technology but also brings new development opportunities to multiple fields such as high-end equipment manufacturing, robotics applications, and security defense.

It is reported that the research findings were presented at the annual International Conference on Mobile Systems, Applications, and Services (ACM MobiSys 2025) held in Anaheim from June 23 to 27, attracting widespread attention. As the technology matures and application scenarios expand, mmNorm is expected to become an important technological breakthrough in the field of high-end equipment manufacturing.