Wedoany.com Report-Jun 4, LG Energy Solution has commenced mass production of lithium iron phosphate (LFP) batteries for energy storage systems (ESS) at its facility in Holland, Michigan, becoming the first global battery manufacturer to produce ESS-dedicated LFP batteries in the United States.

An employee inspects the battery production process at LG Energy Solution’s plant in Holland, Michigan.

This move is part of LG Energy’s strategic response to the temporary slowdown in electric vehicle (EV) demand and intensifying price competition in the global battery market. The company aims to strengthen its presence in the North American ESS sector by offering localized production, which allows it to avoid tariffs and enhance price competitiveness.

A company spokesperson stated: “Producing LFP batteries for ESS locally allows us to avoid tariffs, which gives us a significant price competitiveness advantage over our rivals. We expect this to strengthen our position in the North American ESS market despite policy uncertainties. We will move quickly to meet growing ESS demand from sectors such as data centers and renewable energy.”

The company has already secured supply agreements with energy firms including Delta and TeraGen. LG Energy’s early entry into the U.S. LFP ESS market positions it ahead of other major manufacturers such as China’s CATL and BYD, Japan’s Panasonic, and Korea’s Samsung SDI and SK On, none of which currently operate similar large-scale facilities in the U.S.

The decision to accelerate LFP battery production aligns with two key industry trends: rapid growth in global ESS demand and the suitability of LFP technology for stationary storage. While LFP batteries have traditionally been less energy-dense than nickel-cobalt-manganese (NCM) batteries, they offer advantages in cost and thermal stability, making them well-suited for ESS applications, where space and weight are less critical.

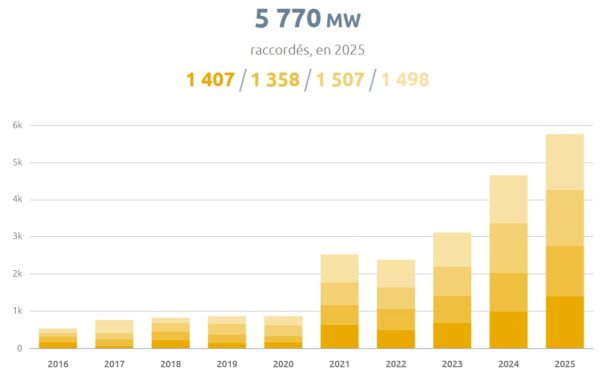

SNE Research projects the global ESS market will grow significantly—from 185 gigawatt-hours in 2023 to 1,232 gigawatt-hours by 2035. Demand is rising not only from renewable energy storage but also from AI data centers, which require stable and scalable power solutions.

Currently, Chinese companies hold over 80% of the global ESS battery market. However, U.S. trade policies, including tariffs and restrictions on Chinese battery imports, are expected to reduce their market share in North America. The U.S. government has already restricted Chinese-made batteries from military facilities, and further regulatory actions remain under consideration.

To capitalize on this shift, LG Energy repurposed part of its existing EV battery plant in Michigan, advancing production ahead of its original 2026 target planned for a separate facility in Arizona. The company estimates it could supply up to 25% of U.S. ESS-related LFP battery demand.

While Korean manufacturers historically focused on NCM batteries, LG Energy and others, including Samsung SDI and SK On, are now revisiting LFP technology. LG Energy also plans to begin mass production of LFP batteries for EVs by the end of this year, with its peers expected to follow in 2025.