Wedoany.com Report-Nov. 6, Clariant, headquartered in Muttenz, Switzerland, has inaugurated expanded advanced facilities at Daya Bay, China, following a CHF 80-million strategic investment. This development markedly strengthens the company's production capacity in a vital growth region.

The upgrade targets two primary sectors: pharmaceutical excipients and specialty chemicals for personal and home care products. This approach aligns with increasing local demand and reinforces Clariant's role as a prominent provider of premium specialty chemicals in Asia.

“This investment represents a pivotal moment for Clariant’s operations in China,” said Christian Vang, Business President Care Chemicals at Clariant. “With these expanded facilities, we are now better positioned to contribute to the health and wellbeing of Chinese consumers while supporting the growth of local industries with our innovative specialty chemicals.”

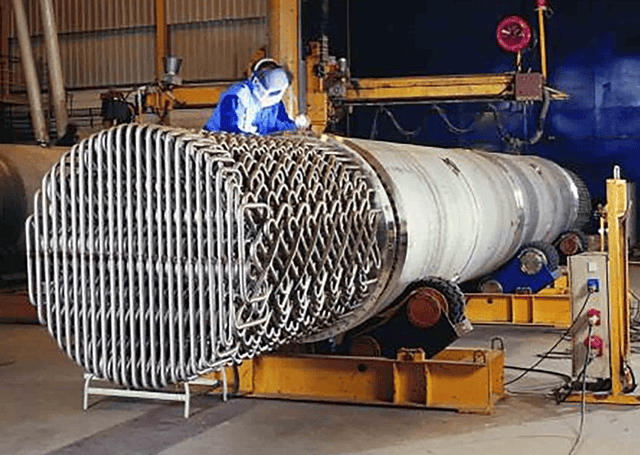

Pharmaceutical enhancements feature a second spray tower tailored for southern China clients, establishing Clariant as a major supplier of active pharmaceutical ingredients for laxatives and excipients nationwide. The site upholds uniform quality benchmarks for healthcare applications globally.

Leveraging over 30 years in polyethylene glycol production, Clariant has boosted Polyglykol output at Daya Bay. The portfolio includes VitiPure™, Polyglykol™, Lanogen™, and Motusflex™—serving as solubilizers, emulsifiers, and solvents in formulations—alongside active ingredients for laxatives and eye treatments.

The multi-purpose plant now incorporates an additional reactor for specialty chemicals, producing mild surfactants for beauty applications and Texcare™ soil release polymers for household products. These meet rising preferences for effective yet gentle consumer solutions.

Further offerings encompass high-performance surfactants for low-VOC water-based coatings, durable synthetic lubricants, precision agriculture additives, and soil enhancers that optimize water and nutrient use. These illustrate Clariant's focus on balanced, sustainable chemical innovations suited to market requirements.

Ethylene oxide derivative capacity and overall chemical range have also grown substantially.

“The evolution of Daya Bay from Clariant’s first ethoxylation plant in Asia to an integrated Multi-Purpose Plant and Ethylene Oxide Derivatives site demonstrates our long-term vision for the region,” explains Christian Vang. “By bringing our innovation and expertise closer to customers, we’re better positioned to help drive their developments forward while addressing our customers sustainability targets and end-product performance needs.”

“This expansion not only increases our production capacity but also enhances our ability to collaborate closely with local customers on tailored solutions,” added Vang. “We’re now better equipped than ever to support the innovation needs of our Chinese customers across the pharmaceutical, personal care, and home care sectors.”

The Daya Bay site anchors Clariant's Asian expansion, particularly in China's dynamic specialty chemicals sector.

This investment enables localized formulation development, shortening lead times and facilitating rapid response to client specifications. Proximity supports joint R&D initiatives, accelerating product customization while maintaining stringent safety and environmental protocols.

Scalable reactor designs accommodate varying batch sizes, enhancing flexibility for seasonal or market-driven shifts. Automated controls ensure consistent output, critical for pharmaceutical-grade materials.

Sustainability integrates throughout, from energy-efficient processes to waste minimization, aligning with broader efficiency goals. The facility's modular layout allows future adaptations without major disruptions.

Clariant's deepened footprint fosters supply chain resilience, reducing dependency on distant sources amid global fluctuations. Collaborative frameworks with regional partners promote knowledge exchange, building technical capabilities across the value chain.

As consumer and industrial needs evolve, the expanded operations position Clariant to deliver responsive, high-value solutions that advance health, hygiene, and performance standards in everyday applications.