Wedoany.com Report-Nov. 6, Carbon Clean, located in London, United Kingdom, and SAMSUNG E&A, based in Seoul, South Korea, have formed an alliance to provide modular, scalable carbon capture systems for industries globally.

The collaboration combines Carbon Clean’s patented CycloneCC™ technology—a columnless, fully modular capture system—with SAMSUNG E&A’s extensive engineering, procurement, and construction expertise and its AHEAD execution model. This integration enables compact, prefabricated units that deploy more quickly, at reduced cost, and with limited site interference.

By merging Carbon Clean’s amine-promoted buffer salt solvent (APBS-CDRMax®) and Rotating Packed Bed technologies with SAMSUNG E&A’s project delivery strengths, the partnership aims to expedite industrial emission reductions and broaden access to capture solutions in challenging sectors.

The AHEAD model streamlines timelines through off-site fabrication, boosts efficiency via early design automation, and minimizes risks for consistent results.

This agreement builds on prior joint efforts with Aramco and MODEC earlier in 2025, showcasing the partners’ proven ability to execute large-scale carbon capture initiatives worldwide.

Aniruddha Sharma, Chair and CEO of Carbon Clean, said: “Our partnership with SAMSUNG E&A marks a major milestone in scaling industrial carbon capture. SAMSUNG E&A’s extensive expertise in scaling up and commercialisation, combined with their core EPC capabilities, will be invaluable as we work together to remove the traditional barriers of cost and complexity and make carbon capture as standard and repeatable as solar and wind deployment.”

Hong Namkoong, CEO of SAMSUNG E&A, said: “We are proud to partner with Carbon Clean to advance practical solutions for a sustainable future. By integrating their breakthrough modular technology with our EPC capabilities, we will accelerate the global rollout of carbon capture systems that are efficient, reliable, and ready for the energy transition.”

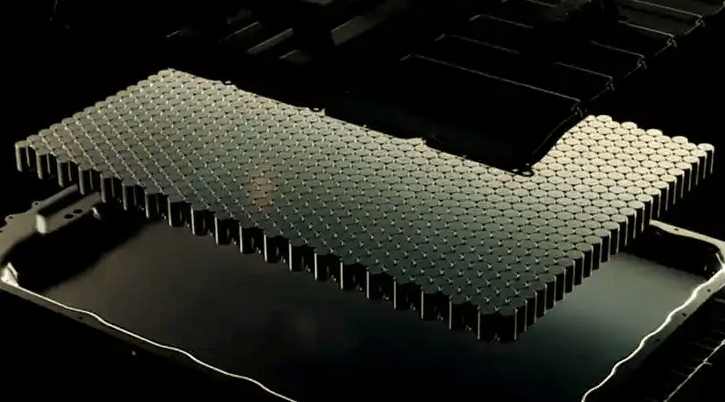

The CycloneCC™ C1 Series offers a compact design—up to 50 percent smaller and ten times more space-efficient than conventional systems—requiring 70 percent less height and 35 percent less steel. Each unit captures up to 100,000 tonnes of CO₂ annually, suitable for emitters with concentrations from 3 to 20 percent.

This modular approach simplifies transport and installation, allowing parallel off-site assembly while civil works proceed. Standardized components reduce engineering hours and enable rapid replication across sites, from cement plants to steel mills.

Prefabrication in controlled environments ensures quality control and weather-independent progress, cutting overall project duration by months. The smaller footprint eases integration into existing facilities, preserving operational continuity.

APBS-CDRMax® solvent enhances absorption efficiency and regeneration energy, lowering operational expenses. Rotating Packed Beds intensify mass transfer, further compressing equipment size without sacrificing performance.

Combined EPC proficiency manages full lifecycle—from feasibility studies to commissioning—streamlining permitting, procurement, and contractor coordination. Digital twins and automated workflows optimize layouts early, preventing costly redesigns.

The alliance targets mid-sized emitters often overlooked by large bespoke projects, democratizing access to proven technology. Flexible configurations adapt to varying flue gas compositions and capture rates, supporting phased implementation aligned with regulatory or corporate timelines.

Early joint ventures validated system reliability under real conditions, building investor confidence for broader rollout. Ongoing R&D refines solvent stability and heat integration, continuously improving economics.

As industries pursue emission targets, this partnership delivers turnkey solutions that balance capital outlay with long-term savings, positioning carbon capture as a viable, routine component of industrial operations worldwide.