Wedoany.com Report-Nov. 23, Larvotto Resources has announced positive metallurgical results from its fully owned Hillgrove gold-antimony project in New South Wales, Australia, achieving a 90% recovery rate for tungsten. The outcome confirms the technical and economic potential to produce a marketable tungsten concentrate as a valuable by-product alongside the project’s primary gold and antimony output.

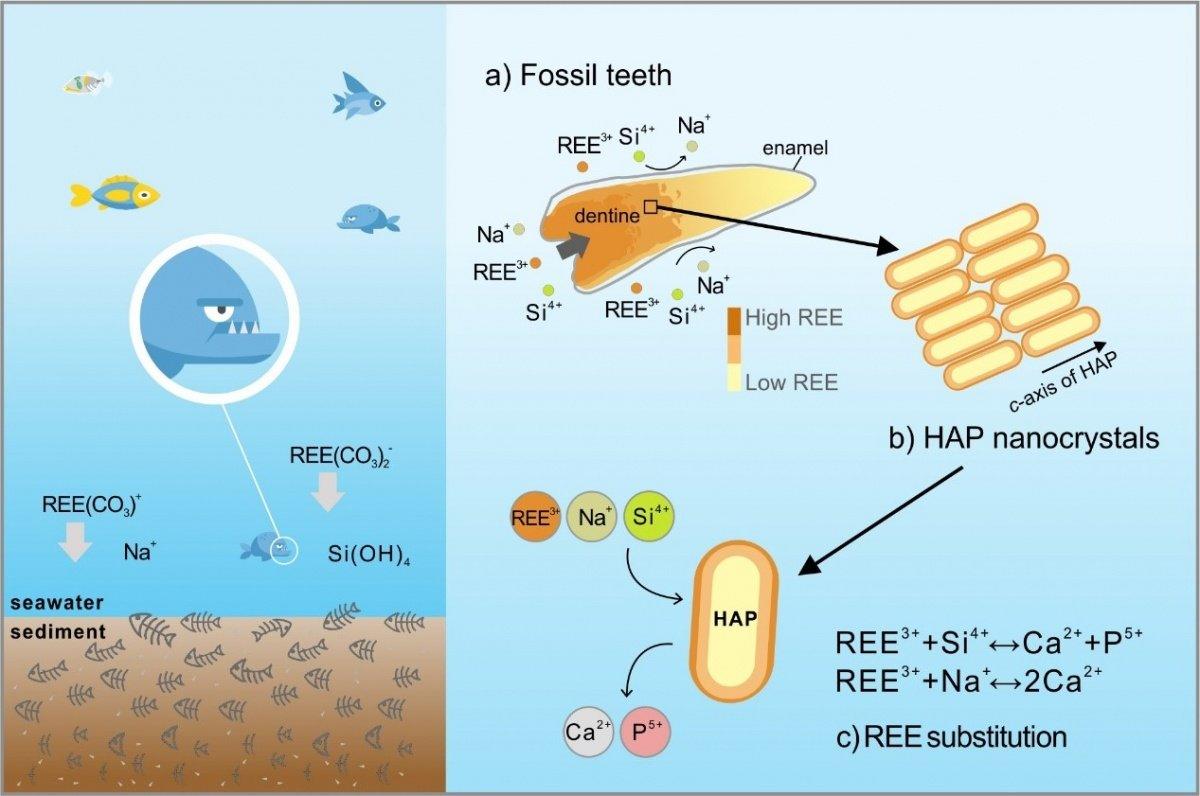

The MRE for Hillgrove stands at 8.77mt at an average grade of 0.05% WO₃, containing a total of 4,774t of WO₃.

The test programme demonstrates that a straightforward, low-cost processing circuit can be added to the existing plant to separate and upgrade tungsten. Further optimisation work, incorporating gravity separation and acid leaching stages, is underway to maximise both recovery and concentrate grade.

Managing director Ron Heeks commented: “Whilst tungsten has historically been mined with antimony and gold at Hillgrove as it is usually present in the same veins, it has never been extracted in the process plant. However, given this year’s record-high tungsten prices, as well as the Hillgrove processing plant already containing a dedicated tungsten gravity circuit that was never utilised, we decided to investigate the viability of tungsten recovery as a byproduct alongside gold and antimony.”

The current Hillgrove mineral resource estimate includes 8.77 million tonnes grading 0.05% WO₃, equivalent to 4,774 tonnes of contained tungsten trioxide. The majority of this tonnage is located in the Brackins Spur and Clarks Gully deposits, both of which remain open for further expansion.

Recent drilling at the nearby Freehold prospect has returned encouraging high-grade tungsten intersections within antimony-gold structures, including 0.6 m at 2.23% WO₃ from 76.7 m in hole SLV004 and 0.5 m at 3.43% WO₃ from 154.8 m in SLV006.

Heeks further stated: “With recent drilling at Freehold confirming that all anomalous tungsten results are associated with antimony-gold mineralisation structures, we remain very enthusiastic about the potential of adding tungsten to our production schedule at Hillgrove.”

Incorporating tungsten recovery requires minimal additional capital because the Hillgrove plant already contains an unused gravity circuit originally designed for this purpose. Successful implementation would create a third high-value revenue stream, strengthening the project’s overall financial returns and extending the economic life of the operation.

Larvotto continues to advance resource definition and process optimisation studies as it moves toward restarting full-scale production at Hillgrove, now enhanced by the prospect of diversified output comprising gold, antimony, and tungsten concentrates.