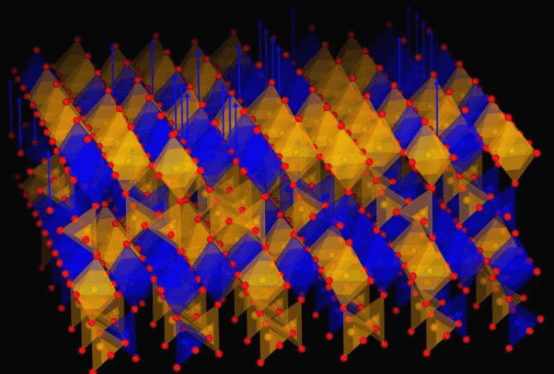

A research team from the Korea Advanced Institute of Science and Technology published their results in Advanced Materials, developing an ultrafast microwave sintering technology that reduces the manufacturing time of solid oxide electrolyzers from tens of hours to 70 minutes. This innovation lowers the sintering temperature from 1400°C to 1200°C, significantly reducing the energy consumption and production costs of green hydrogen energy equipment.

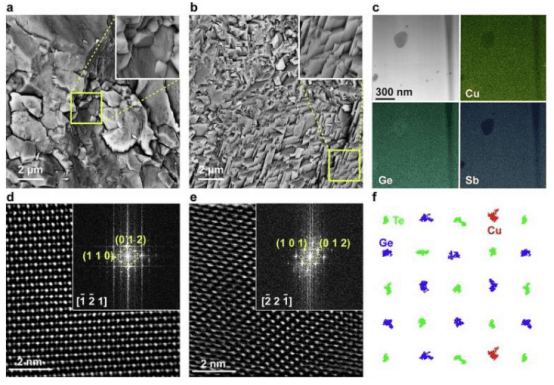

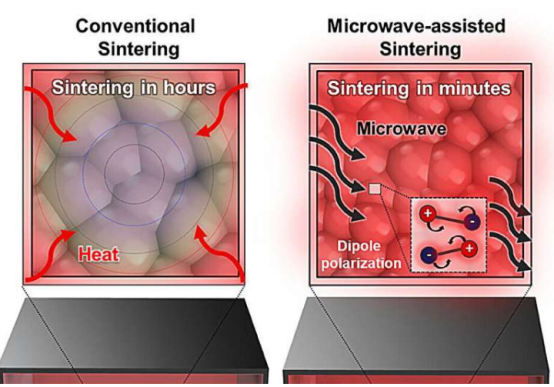

Professor Lee Kang-ze's team adopted a microwave volumetric heating method to achieve defect-free bonding of the ceria-zirconia bilayer electrolyte. Compared to the 36.5 hours required by traditional processes, the new technology shortens the total processing time for solid oxide electrolyzers by more than 30 times. Professor Lee stated: "This research introduces a new manufacturing paradigm that can quickly and efficiently produce high-performance solid oxide electrolyzers. Compared to traditional processes, our method substantially reduces energy consumption and production time, with strong commercialization potential."

The microwave sintering technology completes the key electrolyte forming process in 10 minutes by uniformly heating from the inside of the material, avoiding the material mixing issues caused by traditional high temperatures. Experimental data shows that electrolyzers prepared with the new process can produce 23.7 milliliters of hydrogen per minute at a working temperature of 750°C and maintain stable operation for over 250 hours. Through three-dimensional digital twin simulation analysis, the researchers confirmed that the ultrafast heating process can enhance electrolyte density and suppress abnormal growth of electrode materials.

This breakthrough in solid oxide electrolyzer manufacturing technology provides a new path for the large-scale commercial application of green hydrogen energy. The microwave-assisted process developed by the research team significantly improves production efficiency while ensuring equipment performance, demonstrating promising prospects for industrial application.