Wedoany.com Report-May 28, Thyssenkrupp nucera AG & Co. KGaA, based in Dortmund, Germany, and Fraunhofer IKTS inaugurated a pioneering solid oxide electrolysis cell (SOEC) pilot production plant for electrolysis stacks in Arnstadt, Thuringia, Germany, on May 27. The event was attended by notable figures from science, industry, and regional leadership, including Thuringia’s Minister President, Prof. Dr. Mario Voigt. This milestone advances the strategic partnership between thyssenkrupp nucera and Fraunhofer IKTS, focusing on high-temperature electrolysis technology for green hydrogen production.

In March 2024, the two organizations signed a cooperation agreement in Arnstadt to develop next-generation SOEC electrolyzers. Building on Fraunhofer IKTS’s research, thyssenkrupp nucera is collaborating to scale SOEC technology for industrial green hydrogen production. The pilot plant, designed and built by Fraunhofer IKTS, initially produces stacks in small quantities, targeting an annual capacity of 8 megawatts, forming the core of thyssenkrupp nucera’s future SOEC electrolyzers.

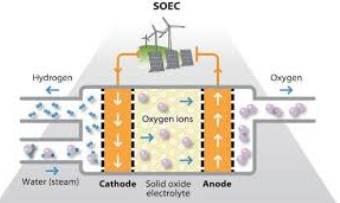

The SOEC stacks utilize an oxygen-conducting ceramic electrolyte substrate with electrodes and chromium-iron interconnectors, ensuring high corrosion resistance, thermal stability, and efficiency. With fewer components than competing designs, the technology is optimized for future automated, large-scale production, enabling cost-competitive manufacturing.

High-temperature SOEC electrolysis offers superior efficiency, requiring less electrical energy to split water vapor at elevated temperatures. When integrated with industrial processes generating waste heat, such as steel production, it can reduce electricity consumption by 20% to 30% compared to other methods. Additionally, SOEC technology can convert industrial CO2 and green hydrogen into green synthesis gas, enabling the production of sustainable chemical feedstocks and e-fuels, supporting decarbonization efforts.

“The outstanding properties of SOEC technology have prompted us to work with our strategic partner Fraunhofer IKTS to develop high-temperature electrolysis to market maturity,” said Dr. Werner Ponikwar, CEO of thyssenkrupp nucera. “We are convinced of the advantages of this electrolysis technology for the production of green hydrogen.”

“By integrating SOEC technology into industrial waste heat sources or directly generating synthesis gas from water and CO2, companies can maximize the efficiency of green hydrogen production and effectively implement their decarbonization strategy,” said Professor Alexander Michaelis, Director of Fraunhofer IKTS.

The pilot plant’s operations will provide critical insights for designing a fully automated, large-scale SOEC production facility. This collaboration strengthens thyssenkrupp nucera’s hydrogen technology portfolio and positions SOEC as a key solution for sustainable industrial applications, contributing to a climate-friendly energy future.