Wedoany.com Report-Nov. 20, Air Liquide has successfully commissioned the world’s first industrial-scale ammonia cracking pilot facility, capable of converting 30 tons of ammonia per day into hydrogen. The unit is located at the Port of Antwerp-Bruges in Belgium and began operations following extensive testing.

This facility represents a major advance in hydrogen supply chains by demonstrating a practical method to transport hydrogen over long distances in the form of ammonia. Ammonia can be produced at low cost in areas with abundant renewable or low-carbon energy, shipped using existing global ammonia infrastructure, and then converted back into high-purity hydrogen at the point of use. The successful operation of this pilot confirms the technical and economic viability of large-scale ammonia cracking plants.

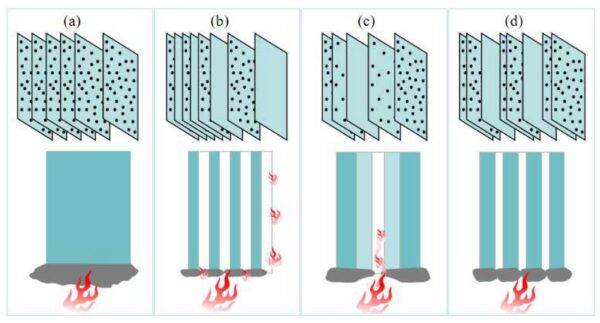

The proprietary technology developed by Air Liquide covers the entire conversion process, including high-efficiency cracking catalysts, safe handling of ammonia combustion, advanced materials, and effective separation of hydrogen from residual gases. These innovations enable the production of low-carbon and renewable hydrogen suitable for industrial applications and clean mobility.

By adding ammonia cracking to its range of hydrogen production methods, Air Liquide strengthens its ability to deliver competitive low-carbon hydrogen to customers in Europe and beyond. The project also highlights the company’s expertise in moving complex technologies from research laboratories to full industrial deployment.

The Antwerp-Bruges pilot serves as a reference for future commercial-scale projects and supports the development of international hydrogen trade routes. It provides a reliable pathway for regions with surplus renewable energy to supply clean hydrogen to energy-importing markets, contributing to the global transition toward lower-carbon energy systems.