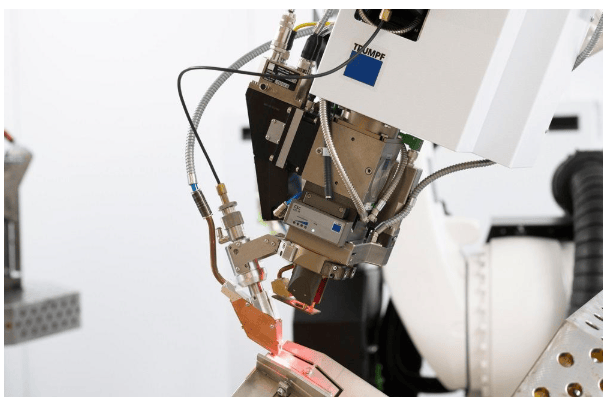

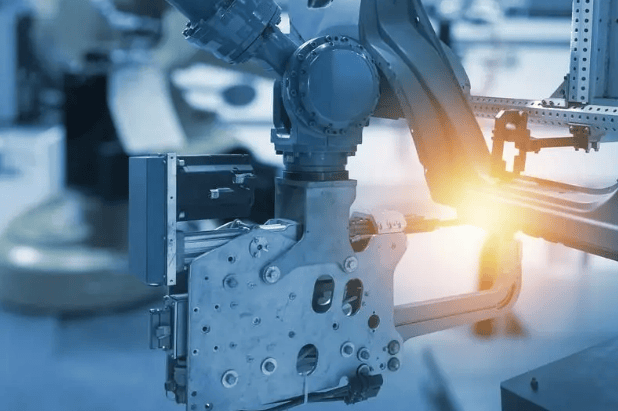

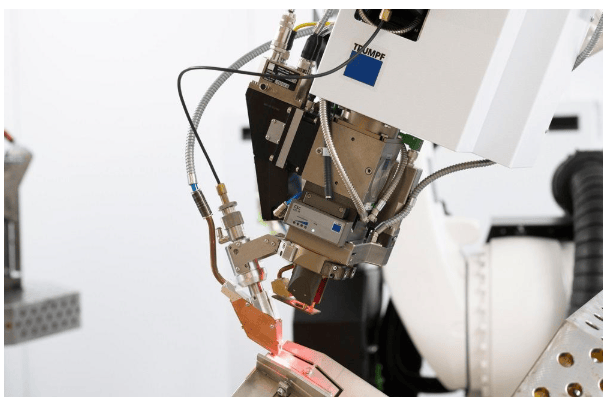

TRUMPF has introduced a laser welding technology called BrightLine Scan, which combines a welding robot with a laser scanner to guide the laser beam for precise welding. The collaborative work between the robot and the scanner, on top of the robot's basic motion, enables free programmable movement of the laser in any direction, thereby enhancing the flexibility and efficiency of the welding process.

This oscillating motion is achieved through lightweight lenses, with scanning frequencies reaching the kilohertz range, allowing the sheet thickness processable in heat conduction welding to increase from 0.12 inches to 0.24 inches. The BrightLine Scan technology allows users to customize the joining surfaces of parts according to specific application requirements. These joining surfaces are formed directly by the melting action of the laser beam, enhancing the adaptability and precision of the weld.

The company states that after the beam is guided by the scanner, it can more easily achieve tighter tolerance requirements. The task of guiding the laser beam is performed by the freely programmable PFO 20 focusing optics, further optimizing welding quality. This robot-optically guided laser welding technology provides new solutions for industrial manufacturing, helping to improve production efficiency and product consistency.