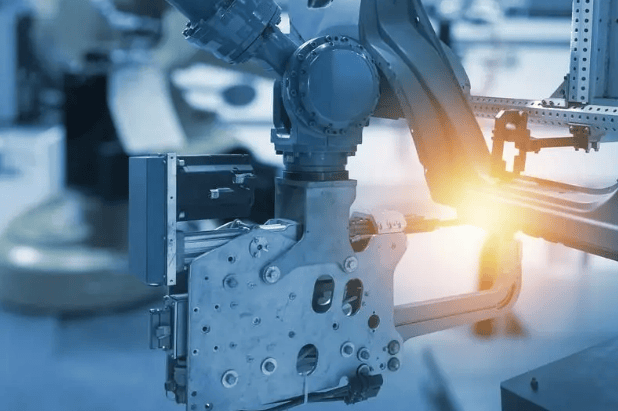

Recently, xTool Company unveiled an integrated workstation named MetalFab, which combines three major functions—fiber laser cutting, fiber laser welding, and laser cleaning—into one compact device. This innovative design aims to help small and medium-sized enterprises reduce their reliance on external processing services, enabling in-house production from raw material cutting to finished product welding.

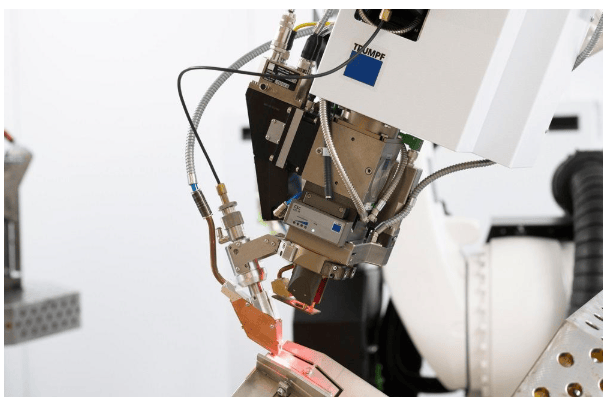

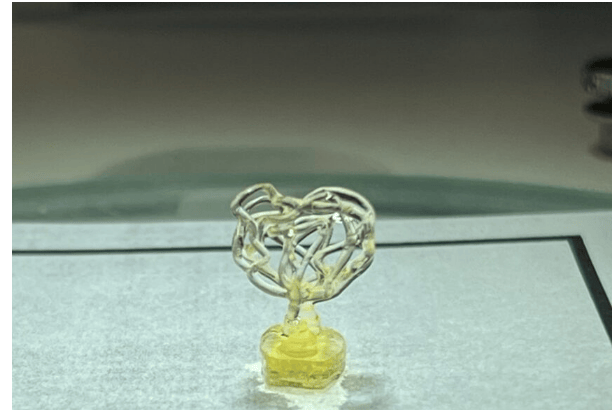

Based on a fiber laser cutting machine, the MetalFab system can efficiently process various metal materials such as stainless steel and aluminum. Users can directly input designs via digital files to quickly generate custom parts and complex structures. The device is equipped with an intelligent switching mechanism, allowing operators to convert the system into a fiber laser welding machine simply by changing the handheld tool. The welding module integrates an intelligent automatic wire feeding system and oscillation welding technology, enhancing welding quality and efficiency.

In addition to cutting and welding capabilities, the MetalFab system also features built-in laser cleaning functionality for removing rust, oxides, and discoloration marks left after welding from metal surfaces. This integrated solution not only streamlines the production process but also reduces equipment investment and operational costs. xTool stated that this system is particularly suitable for small and medium-sized manufacturing enterprises, helping them improve production flexibility and autonomy to meet diverse market demands.