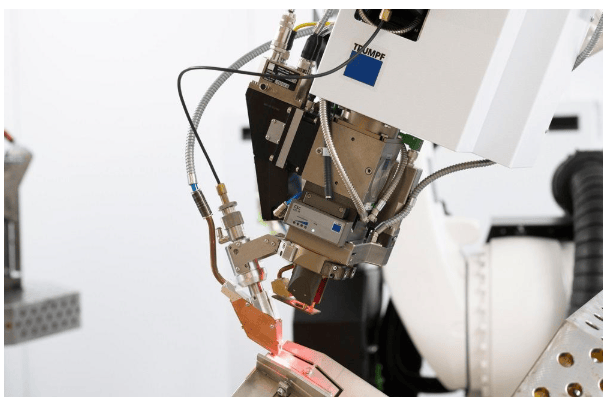

Lincoln Electric recently launched the Flex Lase handheld laser welding system, designed to improve welding speed and quality for materials such as stainless steel and aluminum alloys. This 2-kilowatt device is claimed to be four times faster than traditional TIG welding processes, promising to bring efficiency innovations to the metal fabrication industry.

The Flex Lase handheld laser welding system integrates two welding modes: autogenous and wire feeding, and incorporates Lincoln Electric's HyperFill dual-wire technology. The system is specifically designed for common metal materials such as stainless steel, carbon steel, and aluminum alloys, capable of handling workpieces of varying thicknesses and types.

By focusing heat input, the Flex Lase handheld laser welding system helps reduce deformation and spatter during the welding process, thereby improving welding consistency and finished product quality. The manufacturer states that the system's operation is simplified, allowing even novice operators to quickly master and perform production-level welding tasks.

The complete configuration of the Flex Lase handheld laser welding system includes the Flex Lase 20 power source, Flex Feed 25L wire feeder, industrial cart, and necessary accessories such as laser safety goggles and welding helmets. The introduction of this handheld laser welding system provides a more efficient and convenient solution for welding stainless steel and aluminum alloys.