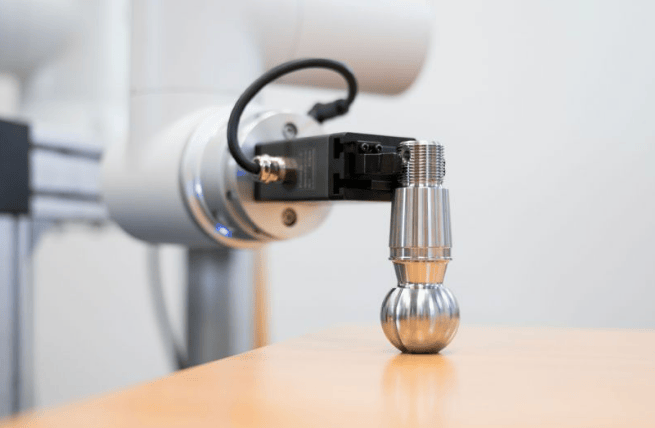

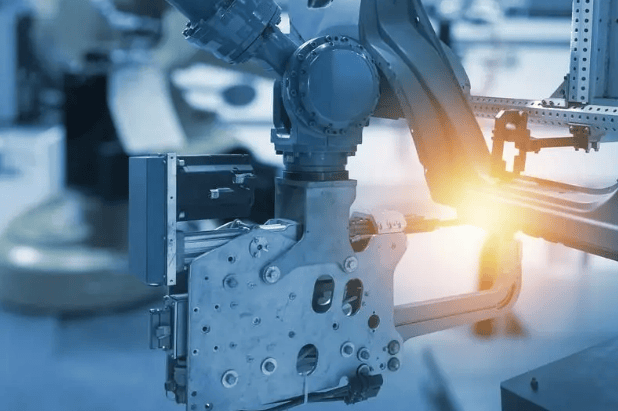

Steering system manufacturer Pailton Engineering is upgrading its manufacturing processes by introducing a collaborative robot (cobot) at its facility in Coventry. The company, which specializes in steering components for military and commercial vehicles, has successfully trialed and invested in the Fairino FR10 cobot for an induction hardening ball stud unit, working alongside employees to boost production efficiency.

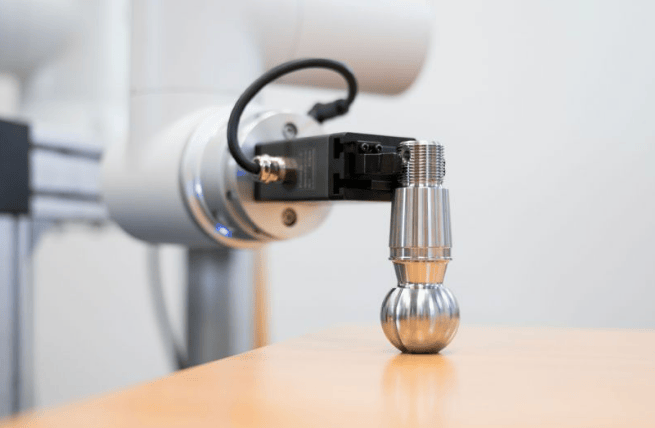

The FR10 cobot is designed to collaborate with humans in a shared workspace, featuring six rotary joints, a payload capacity of 10 kg, a reach of 1400 mm, and a repeatability of ±0.05 mm. Its all-metal structure, combined with high-torque motors, harmonic drive gears, magnetic brakes, and optical and inductive encoders, along with an IP54 protection rating, ensures stable operation in complex environments.

Dave Pound, Managing Director of Pailton Engineering, stated, "This initiative is an extension of our automation strategy. We are advancing more automation applications both inside and outside the workshop, not to replace employees, but to enhance their skills and provide opportunities to learn new technologies."

"Recently, team members have observed an overall increase in digitalization across the factory, and this cobot is gradually adapting to its role. Our goal is to build a collaborative environment that integrates human expertise with robotic precision to jointly drive innovation," he added.

The new configuration also includes additional accessories designed to support flexible automation for precision mechanical assembly and component testing, contributing to improved production consistency and efficiency. Pailton Engineering's automated manufacturing process is being strengthened through cobot technology, optimizing overall operations.

Sebastian Schupke, Sales and Business Development Manager at Fairino Europe, said, "We believe cobots can provide businesses with a pathway to sustainable growth, helping address challenges such as labor shortages while keeping humans at the core of production. We commend Pailton Engineering's commitment to collaborative automation and look forward to future cooperation." This collaboration further advances the application of automated manufacturing in the industrial sector.