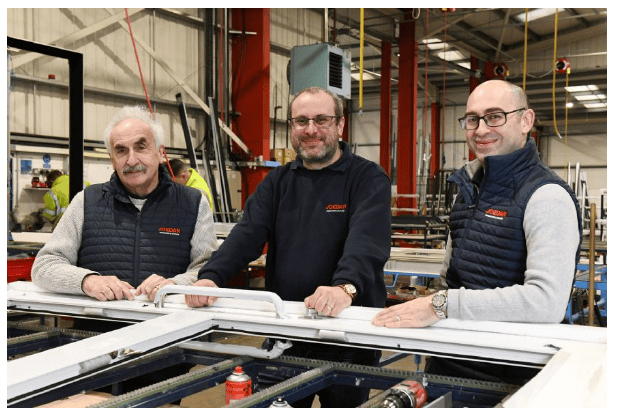

MGS Technical Plastics has strengthened its additive manufacturing and machining capabilities by introducing a new 3D printer and a fourth CNC machine. The Lancashire-based company states that this move helps provide more comprehensive support to OEMs and product developers, covering all stages from concept design to mass production.

Chloe Maine, Business Development Manager, said: "Component manufacturing is a multi-stage process, and the key to success lies in matching specialized expertise to each stage. In-house support reduces risks and accelerates time to market." Managing Director Judson Smythe added: "Early collaboration with customers provides technical guidance, from process to material selection, thereby optimizing product design and commercial viability."

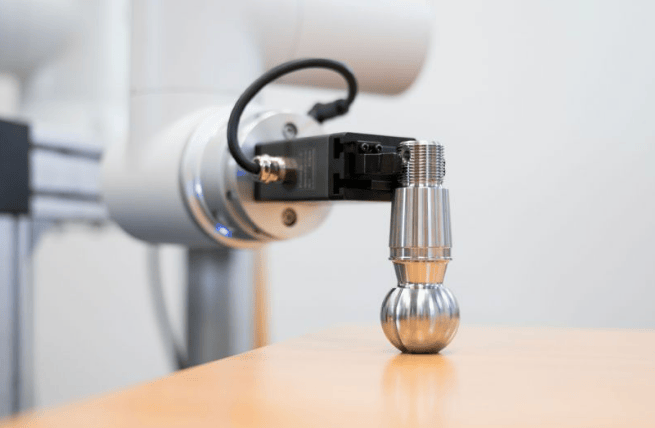

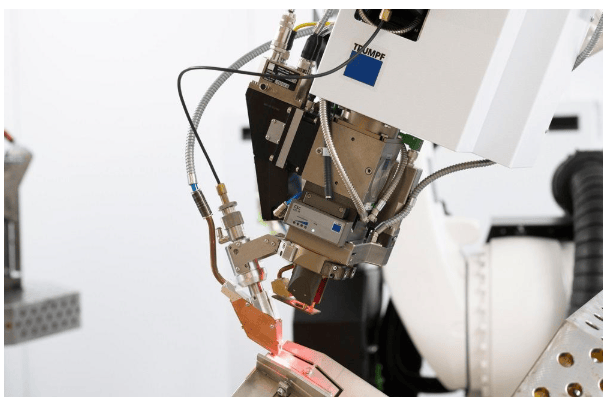

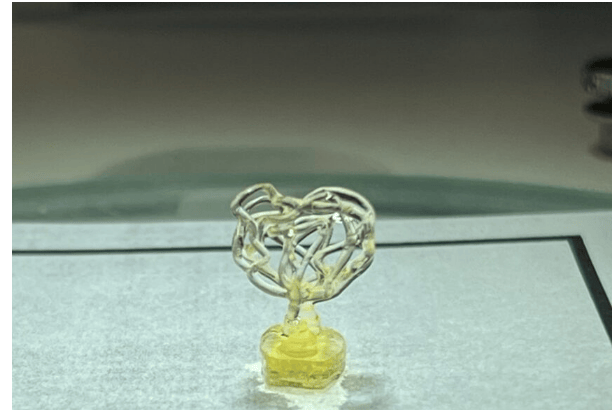

The new 3D printer enables MGS to rapidly produce high-precision prototypes in-house, supporting a "fail fast, learn fast" development model. Commercial Director Mark Preston noted: "This service helps clients mitigate risks before committing to full-scale production. The 3D printer can sometimes reduce development time and cost by up to 70%." For projects requiring small batches or custom parts, CNC machining offers flexible supplementation. MGS has installed a fourth CNC machine to meet this demand.

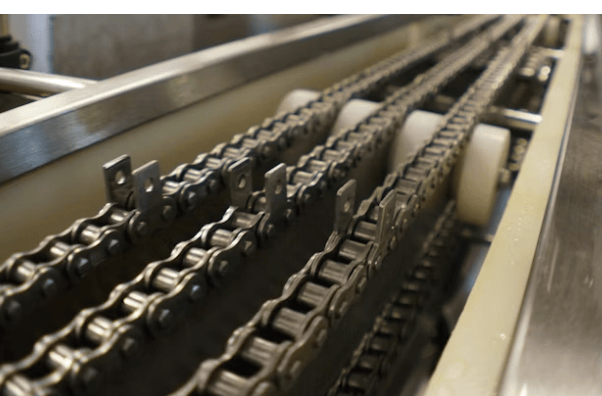

Chloe Maine explained: "CNC machining allows the use of various materials such as metals and composites, making it suitable for small-batch production and pre-production parts." Mr. Smythe mentioned that this technology is often used for manufacturing precision parts and molds in sectors like automotive and aerospace. As production volumes increase, injection molding becomes an efficient choice. MGS's in-house toolroom supports rapid tool modifications. Mr. Preston emphasized: "Injection molding ensures precision and consistency in mass production, offering shorter cycle times and tighter tolerances compared to 3D printing."

MGS Technical Plastics continues to invest in equipment upgrades and employee training, committed to achieving sustainable growth within the UK plastics manufacturing industry. The company's end-to-end service, from prototyping to mass production, aims to provide clients with technical solutions, enhancing manufacturing efficiency and product quality.