A research team at POSTECH has developed a revolutionary dry adhesion technology that enables easy bonding and debonding of everything from microelectronic components to everyday household materials.

The study, recently published in Nature Communications, was led by Professor Seok Kim (POSTECH) in collaboration with Professor Kihun Kim (POSTECH), Professor Namjoong Kim (Gachon University), Professor Haneol Lee (Jeonbuk National University), and Dr. Chang-Hee Son (University of Connecticut).

Micro-LED is a next-generation display technology offering superior brightness, longer lifespan, and the ability to create flexible and transparent displays. However, precisely transferring Micro-LED chips—thinner than a human hair—onto target substrates with minimal residue has remained a major hurdle. Traditional methods rely on liquid adhesives or specialized films, which often result in complex processes, poor alignment accuracy, and contamination.

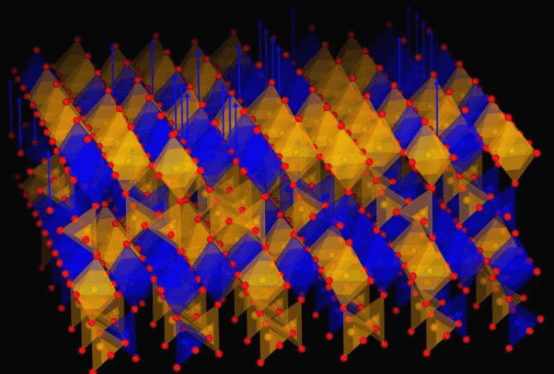

Researchers have also long struggled with the adhesion paradox: theory predicts strong atomic-level bonding between surfaces, yet real-world roughness limits actual contact area, making robust adhesion difficult to achieve.

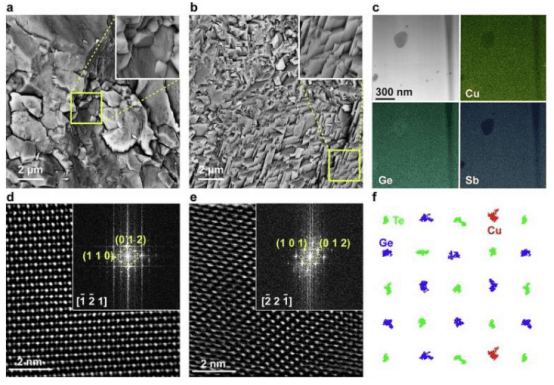

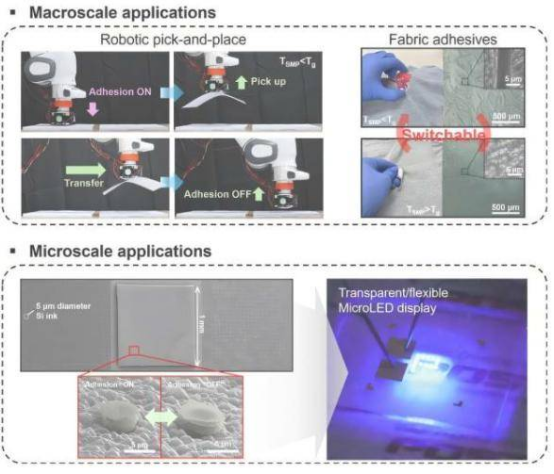

The POSTECH team cleverly turned this paradox into a solution. They developed a surface using shape-memory polymer (SMP) covered with densely packed nanoscale tips. At room temperature, the surface remains rough and exhibits low adhesion. When heated and pressed, the surface smooths out—like ironing wrinkles—dramatically increasing adhesion. Upon reheating, the surface reverts to its original rough state, significantly reducing adhesion and enabling easy release.

This technology delivers bonding strength exceeding 15 atmospheres during attachment and near-zero peel force through self-release. The adhesion strength difference between "on" and "off" states exceeds 1,000-fold—orders of magnitude higher than conventional methods. The team demonstrated precise robotic pick-and-place of Micro-LED chips and confirmed stable bonding even on materials like paper and fabric.

Professor Seok Kim from POSTECH stated: "This innovative technology enables precise manipulation of delicate components without any adhesive. It holds enormous potential in display and semiconductor manufacturing and, when integrated with smart manufacturing systems across industries, could bring about revolutionary change."