Scientists at Tianjin University have developed a pioneering non-destructive testing technology for micro-LED wafers, providing a much-needed solution to long-standing industry challenges through an innovative "soft contact" method.

Micro-LED is widely regarded as the foundational technology for next-generation high-end displays. Achieving near-perfect yields during wafer manufacturing is crucial for ensuring product quality and controlling repair costs. However, the lack of effective non-destructive wafer-level testing methods remains a major technical challenge.

In an article published on June 13 in Nature Electronics, a research team led by Professor Xian Huang from Tianjin University's School of Precision Instrument and Opto-electronics Engineering addressed this critical gap.

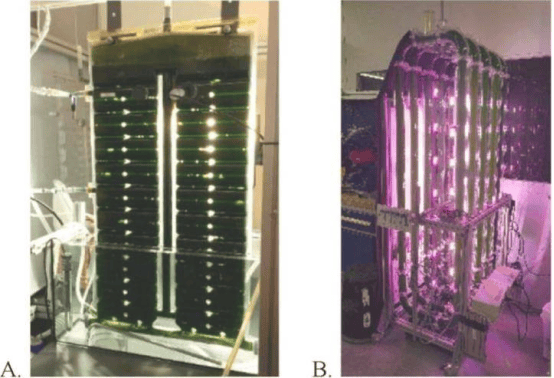

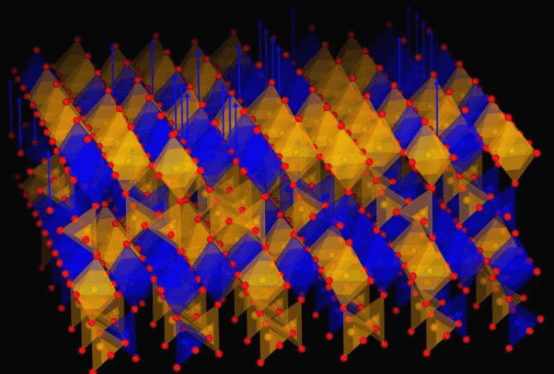

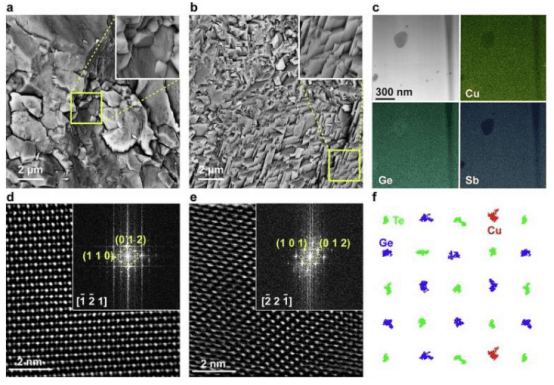

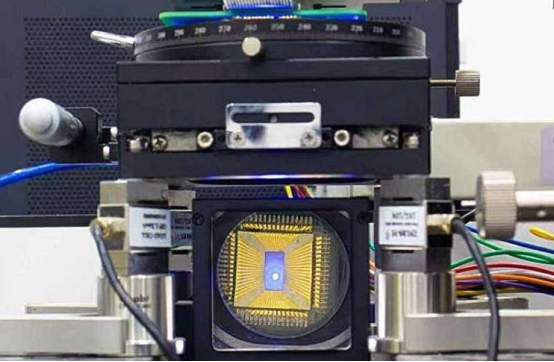

The team introduced a flexible three-dimensional probe array capable of conforming to the micro-topography of micro-LED wafers, applying pressure as low as 0.9MPa—equivalent to the force of a gentle breath. This soft contact method enables high-throughput electrical testing without scratching or damaging the wafer surface.

"Our flexible probe applies contact pressure that is only 1/10,000th that of traditional rigid probes," Professor Huang explained. "This not only protects the wafer surface but also significantly extends the probe's lifespan. Even after one million contacts, the probe remains in its original condition."

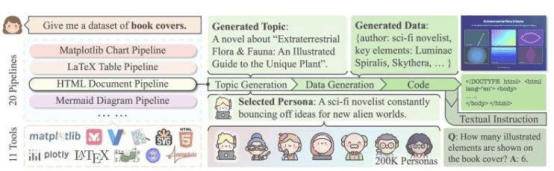

To support this innovation, the team also developed a custom-designed measurement system that integrates seamlessly with the flexible probe. Together, they provide powerful tools for process control and yield screening in micro-LED manufacturing.

Professor Huang stated: "This breakthrough lays a new foundation for the field. It fills a major technical gap in micro-LED electroluminescence testing and paves the way for broader applications in advanced wafer inspection and biophotonics."

Currently, the technology is advancing toward commercialization at Tiankai Higher Education Innovation Park. It holds promise for providing scalable, low-cost, and non-destructive testing solutions to the rapidly growing micro-LED industry while expanding the practical applications of flexible electronics across numerous high-tech fields.