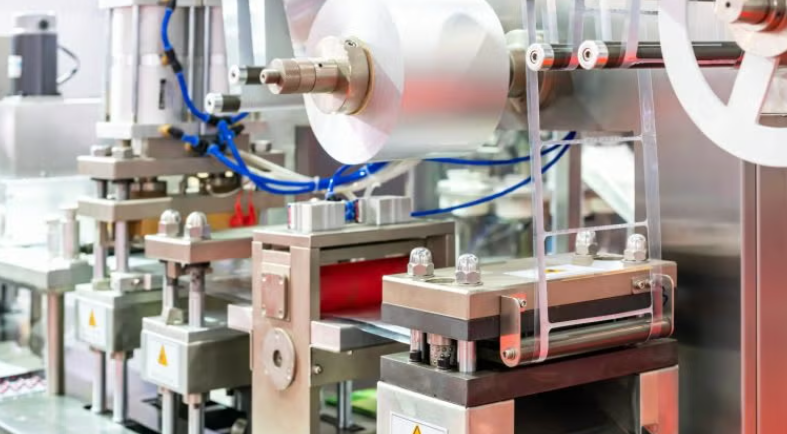

Wedoany.com Report-Nov. 17, Switzerland-based sustainable packaging provider Medipack has integrated Eastman’s Eastar 6763 Renew copolyester into its new medical-grade thermoforming film. The move allows Medipack to offer a lower-carbon alternative without modifying its existing production lines.

Eastar 6763 Renew copolyester contains up to 50% certified recycled content.

The copolyester, used in MEDPETG 6763 RN film, contains up to 50% certified recycled content sourced from hard-to-recycle waste processed through Eastman’s molecular recycling technology. This approach diverts material from landfills and reduces reliance on virgin feedstocks.

Heather Singler, Eastman medical commercial director, said: “We take great pride in making a sustainable option available in the medical market. We couldn’t be happier that Medipack has been able to take advantage of Eastar 6763 Renew to deliver products its customers can count on.”

Medipack has previously used the original Eastar 6763 copolyester in its manufacturing. The company was able to switch to the Renew variant without altering its production process or obtaining additional medical certifications, which are often time-consuming and costly. Eastar 6763 Renew maintains the same certifications and provides sterilisation compliance required for pharmaceutical and medical applications.

Felix Neidhart, Medipack sales manager, said: “Eastman’s molecular recycling technology makes it possible for us to use certified recycled content without compromising quality or safety – an essential requirement in medical packaging. It enables the benefits of recycled content in sterile barrier packaging, which was previously not feasible. This is a major step toward circularity in medical packaging.”

The adoption of Eastar 6763 Renew demonstrates Medipack’s commitment to sustainability and circular economy principles in the medical packaging sector. By retaining the necessary certifications and safety standards, the company ensures that medical-grade performance is maintained while reducing environmental impact.

Eastman’s molecular recycling process converts hard-to-recycle waste into certified recycled copolyester, which can be used directly in production. This approach supports both sustainability goals and the increasing demand for eco-friendly medical packaging solutions worldwide.

Overall, the collaboration between Medipack and Eastman reflects the growing trend in the medical industry to combine high performance, regulatory compliance, and environmental responsibility. By implementing recycled content without compromising quality, the partnership provides a viable path toward more sustainable and circular medical packaging solutions.

The introduction of MEDPETG 6763 RN film is expected to strengthen Medipack’s position in the medical packaging market, offering clients reliable, low-carbon alternatives while advancing sustainable manufacturing practices.