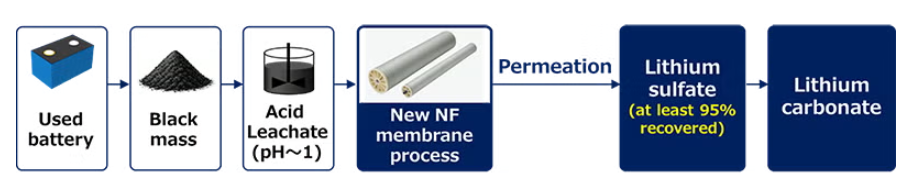

Wedoany.com Report-Dec.9, Toray Industries, Inc. (Tokyo) has developed a scalable, high-durability nanofiltration membrane element that achieves over 95% lithium recovery with high purity from spent automotive lithium-ion batteries, markedly improving on conventional recycling processes that typically discard most lithium.

The breakthrough addresses a growing need in battery recycling as electric vehicle adoption accelerates and nickel- and cobalt-free lithium iron phosphate (LFP) batteries become more common. Toray's technology efficiently recovers lithium from both traditional nickel-cobalt-manganese and LFP chemistries while also enabling extraction of cobalt and nickel when present.

Conventional nanofiltration membranes used for lithium recovery from salt-lake brines lack sufficient resistance to the highly acidic sulfuric acid leachate produced when processing black mass from end-of-life batteries. Toray overcame this limitation through proprietary advances in organic synthesis, polymer chemistry and nanotechnology, creating a membrane that maintains both exceptional acid resistance and precise ion selectivity.

In laboratory-scale tests, the membrane successfully separated and concentrated lithium from sulfuric acid leachate, demonstrating what Toray describes as the world's first membrane-based selective lithium recovery process for battery recycling. Recovery rates consistently exceeded 95% while delivering high-purity output suitable for direct reuse in new battery production.

The company has now successfully scaled the technology to full-size spiral-wound elements compatible with standard industrial module housings used in water-treatment systems. This achievement enables cost-effective mass production and rapid deployment in commercial recycling facilities.

Toray plans to begin supplying evaluation samples to battery manufacturers and recycling companies worldwide, supporting accelerated development of closed-loop lithium supply chains. The innovation is expected to contribute significantly to resource security and sustainability in the global electric-vehicle battery industry by establishing practical, high-yield lithium recycling at commercial scale.